What Kind of Chemical Bonding Occurs Between Dye and Fiber?

Most of the significant properties of a dye depend on the bonds that attach the dye to the fiber. The dyeing method, the parameters that are needed to be followed during the dyeing, and the auxiliaries that are necessary for dyeing are mainly dependent on the chemical bonds between the fiber and the dye. So, it is a very crucial question.

There are different types of dye available, and they get fixed into the fiber differently.

Summary of the Chemical Bonds of Dyes with Fibers (Means of Fixation)

| Dyes | Bonds |

|---|---|

| Direct dye | H-bond, Van der Waals force of attraction |

| Reactive dye | Covalent bond |

| Acid dye | Ionic bond, H-bond also contributes |

| Basic dye | Ionic bond |

| Disperse dye | Physical bond (Trapped) |

| Vat dye | Physical bond (Trapped in a water-insoluble form) |

| Sulfur dye | Physical bond (Trapped in a water-insoluble form) |

| Azoic color | Physical bond (Trapped in a water-insoluble form) |

| Indigo dyes | Physical bond (Trapped in a water-insoluble form) |

There are some ways to improve bonding in wool and cotton.

Firstly, toxic heavy metal ions can be used to create weak attachments, which enhances bonding. The process is known as mordanting.

Secondly, the tannin process is used where a thin film is produced over the fiber surface. The film prevents the dyes from getting out from the surface. Thus, it improves the fastness.

Thirdly, fixing agents can be used that makes the dye molecules bigger by creating a complex with them. Thus, breaking the dye molecules become more complicated, and the bonding is enhanced.

Chemical Bonding Between Dye and Fibers

We have already covered the different types of dyes that are currently available in the market in-depth in our previous post. Here, we’ll only talk about the kind of chemical bonds that attach the dye to fiber.

Direct Dyes

As direct dyes have great substantivity towards cellulosic fiber, they are attached with the fiber by weak bonds, i.e., Hydrogen bond and Van der Waals force of attraction. So, direct dyes show poor fastness properties when compared to the other dyes. And also they are less brighter.

Fiber Reactive Dyes

Reactive dyes, also known as fiber reactive dyes, are mainly applicable to cotton but can also be applied to protein and polyamide. These dyes create a covalent bond with the fiber by sharing electrons between atoms. It is a strong bond, and the dyes become a part of the fiber structure. So, the fastness properties of reactive dyes are good. A good example is the Procion MX Dyes that contain the dichlorotriazine reactive groups.

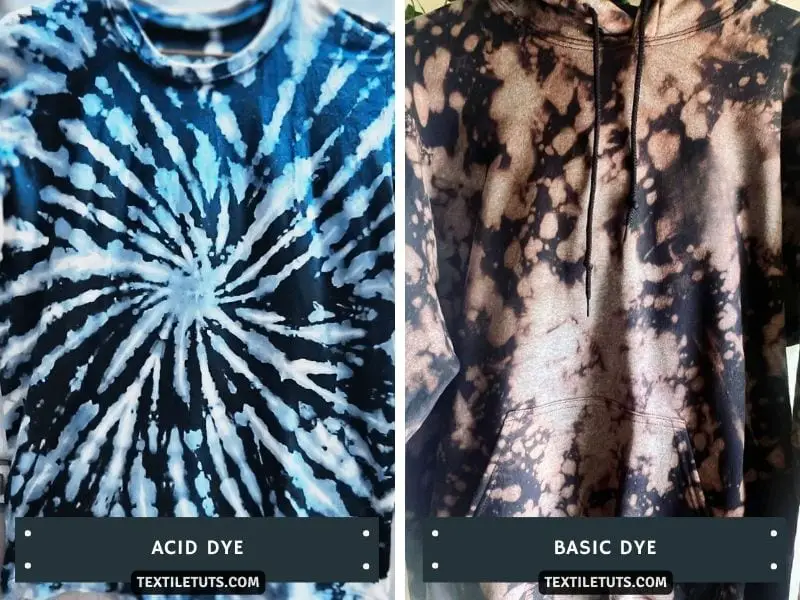

Acid Dye and Basic Dyes

Acid and basic dyes are mainly applicable to polyamide fibers and acrylic fibers. Different bonds contribute to acid dyes. The amino acids in protein fibers have several side chains, and various types of acid dyes can join with those side chains with Hydrogen bonds at different pH.

Most of the acid dyes have sulphonic and carboxylic groups present in their structure, and they create salt linkages with the fiber, i.e., ionic bonds. These bonds form between opposite charges as acid dyes are anionic, and wool or nylon becomes cationic in particular conditions. The bonds are strong. As a result, acid dyes show excellent wash fastness properties.

They are similar in the case of basic dyes too.

The above dyes create chemical bonds with the textile material. But some dyes create physical bonds. They are either physically trapped inside the fiber pores or trapped by becoming water-insoluble form.

The following dyes create physical bonds.

Disperse Dyes

Disperse dyes, the best fabric dye for polyester, are physically trapped inside the pores of polyester. At glass transition temperature (Tg), polyester becomes rubbery, and around 110°C temperature, the pores start to open.

The dye molecules get inside the pores, and when the temperature is lowered, they get trapped inside the pores. These are physical bonding, not chemical bonding. That’s why disperse dyes show excellent wash fastness properties.

Vat and Sulfur Dyes

They get trapped inside the fiber in an insoluble form when applied to cellulosic fibers. We know that vat and sulfur dyes are water-insoluble. They are made water-soluble by reduction, which makes them leuco soluble. When dyeing is finished, oxidation is carried out to make them insoluble again like the parent. It is also a physical bonding.

They show excellent wash fastness. But if the dye molecule can not penetrate inside the fiber properly, ring dyeing occurs. This allows the dyes to fade away due to abrasion and rubbing. The exciting thing is that this property is appreciated for the jeans and denim.

Azoic Colors

They are also get fixed in the fiber in water-insoluble form. The bond formation of azoic color is very interesting. They need two components. The coupling components, naphthol, made water-soluble by naphtholation, and the diazonium salt produced by diazotization is mixed to create colors and get fixed in the fiber. The various combination of coupling component and diazonium salt provides different colors.

As the application of azoic dyeing is toxic and very low temperatures are required, the dyes are not widely used.

Indigo Dyes

They are one kind of natural dyes, but they generally fall in the category of vat dyes. Like vat dyes, they also get trapped inside the fiber by becoming water-insoluble due to oxidation.

Natural Extracted Dyes

Most of the natural dyes are not substantive to textile material. They need mordanting agents to get fixed in the fiber. So, generally, natural mordanting agents are used to make the dye molecules create a bond with the fiber. The whole process includes pre-mordanting, meta-mordanting, and post-mordanting typically.

REFERENCE