What is Interlining | Types of Interlinings

Among the various vital accessories that are used in a garment as an integral part, interlinings are the most functional ones. Along with imparting many functional attributes, they improve on the aesthetic appeal of the garment as well. You probably know them as embroidery stabilizers. Anyway, let’s start with the basics.

What is Interlining?

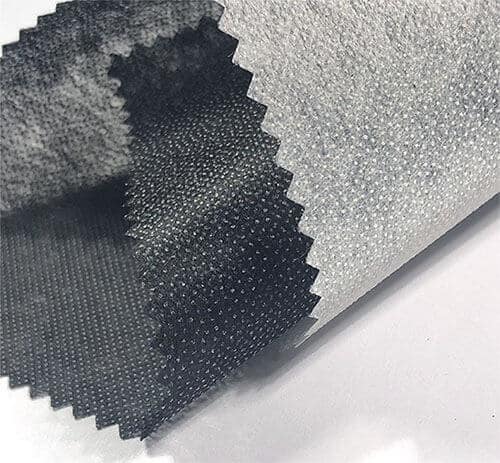

A piece of fabric used for a particular part/component, used between two plies of actual garments to provide

- Attractiveness

- Strength

- Shape Retention

is called interlining. By and large, interlining is utilized in the garments like the neckline, belt, confronting, forward portion of a coat. Interlinings are delicate, thick, and adaptable. Its texture comes from the material that’s used to make it, i.e., the filaments of cotton, nylon, polyester, fleece, or with their mixes. Interlining fabric is fabricated by weaving, sewing, or by felting(nonwoven). These fabrics are given treatment for accomplishing unique characteristics

Garments segments that are customarily fused are:

- Skirts and pants: belts, overlap, underlap;

- Blouses, shirts, and dresses: collars, facings, cuffs;

- Coats and jackets: fronts, facings, collars, pocket folds, pocket openings, and so forth.

Imbuing blouse and dress parts (contingent upon the face fabric characteristics), just one kind of interlining is utilized.

Two sorts are utilized in the segments of skirts and pants: gentler interlining to take into consideration the clasp and harder, thicker interlining for the belt.

At least three interlinings might be utilized for coats, as indicated by the size and capacity of the face fabric segments. For instance, the fronts and facings of women’s jackets are melded with hard interlining. While collars, the front of armholes, and pocket openings utilize gentler interlining. The gentlest interlining is used for the upper piece of backs, the rear of armholes, sleeves, and the bottoms of coats. In any event, 90% of melding is done on little parts such as sleeves, collars, belts, belts, epaulets, and plackets.

Why Use Interlining?

The followings are the essential target of utilizing interlining in garments –

- Interlinings are primarily utilized for giving quality/backing, security, and shape maintenance.

- At the point when melded to the external shell fabric, it goes about as a composite. Thus balances out the outer shell against any contortion under pressure

- Improves tasteful and hand feel of fused laminate

- Holds the state of the combined part during use and aftercare treatment

- Improves the life span of the melded part

Interfacing vs Lining vs Interlining vs Underlining

These terms allude to development subtleties that are generally escaped see when you’re wearing an article of clothing. Yet, they serve a significant capacity fit as a fiddle and solace of your creation.

Interfacing is a type of fabric utilized additionally in regions where more strength is required than merely the texture weight. For instance, interfacing is found in belts, clothing collars, sleeves, terminations, and in some cases, hems. So, you can say it works as a fabric stiffener agent. In custom-made garments, interfacing can be found under the whole piece of clothing areas, and greater than one sort is utilized inside a solitary article of clothing. In some cases, felt can be used instead of interfacing.

The lining is utilized to help shroud the internal development subtleties of an article of clothing, and to assist it with sliding now and again over other garments easily. Fabrics used for lining are generally slippery and silky; however, different sorts might be utilized for impact. The lining is built independently from the whole garment and joined at confronting or hem regions by machine or hand.

Interlining is added to create a warmer feeling to garments if required, as in a coat for winter. It might be a substantial texture with batting included or like wool or downy, which is lighter in weight. It can be built independently from the real garment (it’s occasionally removable) or utilized as underlining.

Underlining is a kind of fabric that is added to mold fabric for making the fabric opaque or covering more body. It’s a different layer connected to the relating piece of clothing texture area wrong side and afterward processed as one while developing. Markings of patterns are frequently moved to them (underlining) to keep away the transparency of the garment fabric.

Types of Interlining

The interlinings can be classified by the following categories.

According to the Application

- Sewn interlining or non-fusible interlining

- Fusible Interlining

According to Fabric

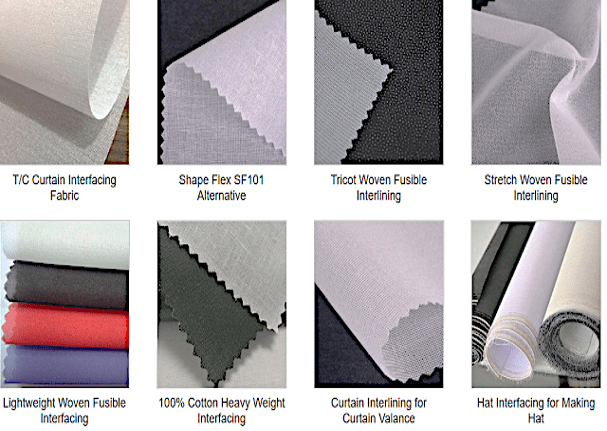

- Woven Interlining: – Woven Interlinings produced using lightweight textures usually utilized for most requesting conditions like the belt, outerwear plackets, coats, and so on.

- Knit interlining – Fusible, knitted interlinings are fundamentally utilized in knit articles of clothing. Different types of fusing are utilized depending on the desired result. Sometimes with stretchable intertwined regions too. These give the ideal premise to proficient creation. Circular and jersey knit fusible interlinings have stretch and recuperation properties.

- Non-oven interlining – High-quality nonwoven interlining is produced using 100% polyamide items with an ultra-fine covering to heavier mixes. These are thermally or synthetically reinforced and utilized, relying upon applications. For the most part accessible in extremely light loads of 100 gms up to 100 gms. They can also be used as modern quilt backing fabric materials.

According to Resin Properties

- Polyethylene (P.E.) coated interlining

- Polypropylene (P.P.) coated interlining

- Polyamide (P.A.) coated interlining

- Polyester coated interlining

- Polyvinyl Chloride (PVC) coated interlining

- Polyvinyl Alcohol (PVA) coated interlining

Sewn Interlining

Sewn interlining has been being utilized for making articles of clothing since old occasions. Sewn interlining is made by consolidating various layers of texture and sewing habitually. Finally, applying into it into the starch-like material, its quality is improved. Sewn interlining is gotten together with the primary texture of the articles of clothing by sewing.

Sewn interlining might be of various characteristics. Its characteristics rely upon,

- The sorts of the snoozes

- Texture development

- The thickness of the interlining, and afterward completed that have been given on it, and so forth.

The quality standard of sewn interlining relies on how dexterously the interlining has been gotten together with the primary textures of the articles of clothing.

To make the sewn interlining and afterward to join the primary textures takes nearly much time. The utilization of sewn interlining has been exceptionally constrained these days as a result of the quality, cost, and time. Sewn interlining has been being utilized uniquely in situations where the utilization of fusible interlinings is poorly arranged. For instance, it tends to be said that on account of fire-resistant pieces of clothing, no other interlining than sewn interlining can be utilized.

The uses of sew-in interlining are given beneath:

- Used as interlining material in fire-resistant articles of clothing, particularly for fire administration individuals.

- Protective pieces of clothing for individuals working in rerolling plants.

- Specially used in embroidery machines.

Advantages of Sewn Interlining

- To make fire-resistant pieces of clothing.

- Basic and simple procedure.

- No intricate machine is required.

- Conceivable to use in steel or rerolling or exceptionally warmed industry.

Disadvantages of Sewn Interlining

- Quality isn’t acceptable when contrasted with the fusible coating.

- Not reasonable for huge production.

- Not accessible in the market, so we have to set it up.

- Additional time required.

- The high outstanding task at hand and work cost.

Woven Interlining

Woven interlinings were first utilized 100 years back to reinforce/bolster coats, cloaks, and grown or cap. It was predominantly 100% cotton fabrics made firm by starch application and was non-fusible. Be that as it may, the terrible hard touch and sporadic attributes during washing prompted the improvement of fusible interlinings.

Typical cotton sheeting fabrics were applied with a layer of cement that can be fixed to the shell fabric by the use of warmth or weight. This framed a composite piece of the combined shell part and upheld the external shell for better wrap and look. For bulk production, there are various types of fusing machines available nowadays.

Woven interlinings are significantly 100% cotton-based with a thread density of variable consider required for the weight or solidness necessary for a specific use. Presently poly-cotton mixes are likewise accessible to beat the issues of shrinkage looked in cotton textures along with an assortment of twist and weft blends like rayon, texturized poly, and wool, and so forth.

Advantages of Woven Interlining

- The primary bit of leeway of woven fabrics is its quality and steadiness, henceforth utilized for every single such application where strength and stability required like the belt.

- In any case, this could be a drawback now and again where adaptability and delicate hand feel are required.

- Woven is significantly plain weaves, now and then crepe, herringbone, or twill weaves are likewise offered by the application need.

- Texturized poly yarns are utilized for the voluminous body in such cases. It is also done for the delicate and regular hand feels, or drape of the infused composite. Simultaneously, the strength, adaptability, and lightweight of the fused overlay are accomplished much by way of modifying the normal wrap or surface of the shell fabric.

- In any case, woven is costly and not reasonable for more affordable easygoing garments; subsequently, it was supplanted by knitted fabrics that utilized a mix of manufactured yarns with rayon and wool for body and volume as per various applications proposed for.

Knitted Interlinings

The significant disservice of woven in its adaptability, lightweight, and the delicate handle was tended correctly to by knitted fabrics. Knitted fabrics have an enormous number of factors regarding loop structures to bestow adaptability/stretch along with the body (volume) and strength/stability.

They are kept lightweight and delicate hand feel of the overlay by utilizing fine built (texturized) fibers. It is costly and subsequently used in high-esteem pieces of clothing like coats and high design blouses.

Nonwoven Interlinings

As the name suggests there is no contribution of any yarn for interlacement to make the fabric.

It is made legitimately from fiber to fabric stage in the process, decreasing the expense of the base fabric. As there is no yarn utilized in making nonwovens, it comes up short on the strength required for apparel use, and there are numerous methods applied to bestow expected solidarity to nonwoven materials, called Bonding.

They are the most adaptable item accessible from 10gsm to 200gsm or more, offering light, delicate, adaptable, or solid for any application one can consider. The essential assembling method is utilizing, for the most part, manufactured filaments to frame a layer, which is conferred strength by holding.

Nonwoven cottons are often used as insulated batting fabric.

Difference Between Fusible Interlining and Non-Fusible Interlining

| Parameters | Fusible interlining | Non-fusible interlining |

|---|---|---|

| Time | Less time consuming | More time consuming |

| Labor cost | Less | More |

| Operating Skill | Anyone can do this process | Experience worker is needed |

| Quality | Quality is consistent | Quality varies according to naps, fabric construction, thickness of the interlining, finishing, skill of the workers, etc. |

| Availability | Sufficient quantity of fusible interlining is available in the market | Less available compare to fusible interlining. |

| Joining process | Joined with the fabric with help of heat and pressure | Joined with the fabric with the help of sewing. |

| Application | Woven, knitted or felted fabrics. | Flame retardant garments |

| Production | More | Less |

| Temperature | High temperature is required | No need of temperature |

| Machine | Elaborate machine is required | No need of elaborate machine |

Can Interlining Be Used as a Double-Sided Fabric Tape?

You can, but it wouldn’t be worth the trouble. The best double sided tape for fabric can make that way easier for you. Typically, interfacing requires somewhat complicated application procedure than fabric tapes.

I hope by now you have a clear idea about what is interlining and the types of interlining.

REFERENCES