What is Fabric GSM and How to Measure It

When we’re out to buy fabric for our crafting needs, one term we often hear is fabric GSM. Even when you take a close look at the hang tag of a garment, you’ll see it there. It’s a very important attribute of a garment because along with many other factors the price and comfort depend heavily on it. Also, different type of knitting stitches and woven structures give rise to different GSM values. Understanding GSM, or grams per square meter, is essential for crafters and consumers alike, as it indicates the weight and density of the fabric. Higher GSM fabrics tend to be thicker and more durable, making them ideal for certain projects, while lower GSM fabrics are lighter and often more breathable. For those looking to delve deeper into the subject, various fabric types explained in detail can help clarify how different materials and construction methods can influence GSM and overall fabric performance.

In this article, we’ll provide you an in-depth look into what is fabric gsm and how do we measure fabric gsm.

Without further ado, let’s jump right in.

What is Fabric GSM: Fabric GSM Meaning

GSM stands for “Gram per Square Meter.” Therefore, we can say it’s a measure of fabric density, i.e., the weight of the fabric per square meter. By evaluating the fabric GSM value, we can assess whether the fabric is heavy or lightweight. The higher the GSM, the heavier it weighs and vice versa. It’s an essential parameter in the textile sector for obvious reasons. For example: it’s an important parameter for a basic t-shirt fabric consumption calculator.

We can’t characterize a fabric without mentioning it. We can measure GSM for all types of fabrics. It’s an essential parameter of the garments ordering process. Thus, maintaining it in all stages of the production is of utmost importance. For this, every textile engineer, specially merchandiser of woven and knit garments, should know the GSM calculation to execute the order properly.

Now, we must remember that while fabric GSM gives us the idea of its weight it’s not a clear indicator of its thickness. The fabric thickness mainly depends on its structure/ construction.

What Is Crimp Factor or Crimp Percentage?

During the calculation of fabric GSM, the crimp factor may be needed sometimes, and for that reason, we have to know the crimp percentage.

Warp and weft yarns are used to form fabrics. These two sets of threads, i.e., warp and weft yarns, create the structure of cloth by interlacing with each other. Due to the interlacing of these two sets of yarn, a wavy structure formed. This waviness is called Crimp. And Crimp always expressed in percentage. Here, the yarn loses its length while forming a wavy formation.

The normal length of the yarn is longer than the interlaced one. That means the threads that are used to create interlacing lose its length due to wavy formation. Suppose a yarn whose length is 5.5 meter in normal or in straight condition, but when it interlaces with another one and form a fabric, then it loses its length, and the length is 5 meter(0.5 meter loss).

Crimp Percentage Measurement

For measuring the GSM, we need to measure the crimp percentage first. The measurement of warp crimp and weft crimp percentages formula are mentioned below:

Crimp Percentage of Warp Yarn

You need to use the following equation to get the crimp% of the warp –

Crimp% of Warp Yarn = {(Length of the Warp in Straight Condition – Length of the Warp in Fabric Formation) ÷ Length of the Warp in Fabric Formation} × 100

Crimp Percentage of Weft Yarn

You need to use the following equation to get the crimp% of the weft –

Crimp% of Weft Yarn = {(Length of the Weft in Straight Condition – Length of the Weft in Fabric Formation) ÷ Length of the Weft in Fabric Formation} × 100

GSM Calculation Method for Woven Fabric

We can use this formula to determine the GSM of given woven fabric:

Woven Fabric GSM = [{(Ends Per Inch × Warp Crimp Factore) ÷ Warp Count} + {(Picks Per Inch × Weft Crimp Factore) ÷ Weft Count}] × 23.5

Now by putting down all the value from a sample, we can easily determine GSM value for a woven fabric.

GSM Calculation Method for Knit Fabric

We can use either of these formula to determine the GSM for knit fabric:

Fabric GSM with Direct Count(Tex) = Course Per Inch × Wales Per Inch × Stitch Length in mm × Yarn Count in Tex × 0.001549

Fabric GSM with Indirect Count(Tex) = (Course Per Inch × Wales Per Inch × Stitch Length in mm × 0.9155) ÷ Yarn Count in Ne

How Does GSM Cutter Machine Work

Basically, the GSM cutter machine works through its Four highly sharp blades. The blades are fitted inside the machine and sorted out in a pattern as every blade can participate in cutting in sequential order and cut the fabric very smoothly. A plate covers the outer part in which blades lie inside. As the blades are highly sharp, so we have to be careful while cutting fabric.

There are machines of various diameters, but for use in textiles, the ideal diameter is about 11.2 cm.

A cutting pad is an inescapable item for GSM cutter. It is also known as GSM PAD. GSM pad is mainly used to avoid crinkles and crease from the fabric during cutting. It helps to get the actual value of GSM.

Alternatively, you can use an online fabric GSM calculator if you don’t have a GSM cutter.

How to Measure Fabric GSM by a GSM Cutter Machine

Measuring Fabric GSM by a GSM Cutter Machine

Actually there are two methods for measuring GSM; one with a GSM cutter and the other without it. Here, we’ve discussed the method with the GSM cutter. But if you don’t have a GSM cutter, then read our article on how to find GSM of fabric without GSM cutter.

Step 1: Condition the Fabric

Firstly, take a sample from the main fabric and reserve it for conditioning. The conditioning time may vary from fabric to fabric because it depends on the nature of the fabric.

Step 2: Placing It over the GSM Pad

When the conditioning time is over, then the fabric is placed on the GSM pad to avoid crinkle and crease. Then the GSM cutter is placed on the fabric.

Step 3: Cut the Fabric

Now, with the hand-driven metal knob, we have to cut the fabric, maintaining a steady pressure. And thus, the fabric is finally cut into 11.2 cm in diameter.

Step 4: Weigh the Fabric

Then we have to move the machine and take the fabric for weighting on the electronic balance to have an accurate measurement.

Step 5: Calculate the GSM

The formula for measuring GSM by GSM cutter machine:

GSM= Specimen weight(gm) × 100

After weighing the value of the cut specimen, we have to multiply the value with 100 and then calculate it. The calculated result is the GSM value for the fabric.

Important Notes

For more accuracy, we should cut the fabric sample from five different places of the main fabric and measure the weight. After calculating the mean value, we have to multiply it by 100 just like before.

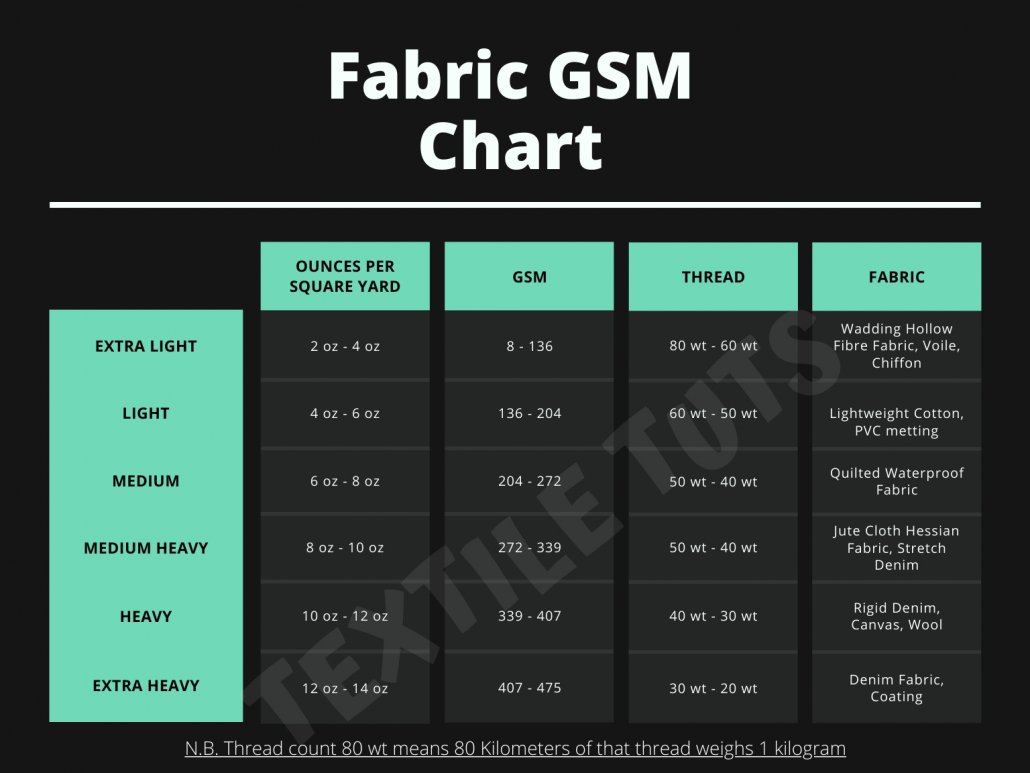

Fabric GSM Chart

| CATEGORY | OUNCES PER SQUARE INCH | GSM | THREAD | FABRIC |

|---|---|---|---|---|

| EXTRA LIGHT | 2 OZ – 4 OZ | 8 – 136 | 80WT – 60WT | WADDING HOLLOW FIBER FABRIC, VOILE, CHIFFON |

| LIGHT | 4 OZ – 6 OZ | 136 – 204 | 60WT – 50WT | LIGHTWEIGHT COTTON, PVC METTING |

| MEDIUM | 6 OZ – 8 OZ | 204 – 272 | 50WT – 40WT | QUILTED WATERPROOF FABRIC |

| MEDIUM LIGHT | 8 OZ – 10 OZ | 272 – 339 | 50WT – 40WT | JUTE CLOTH HESSIAN FABRIC, STRETCH DENIM |

| HEAVY | 10 OZ – 12 OZ | 339 – 407 | 40WT – 30WT | RIGID DENIM, CANVAS, WOOL |

| EXTRA HEAVY | 12 OZ – 14 OZ | 407 – 475 | 30WT – 20WT | DENIM FABRIC, COATING |

N.B. Thread count 80 wt means 80 kilometers of that thread weighs 1 kilogram.

What Is the Relationship Between Yarn Count and Fabric GSM?

Yarn count is a measure of a yarn’s linear density and is used to identify the thickness of the yarn. On the other hand, GSM is a measure of fabric’s weight per unit area and is used to identify the relative weight of a fabric. We have already built a yarn count to GSM calculator which can be used to convert yarn count to GSM and vice-versa.

Frequently Asked Questions

1. What is GSM tester?

GSM tester is a type of machine through which the GSM value is obtained by cutting a sample from the main fabric directly.

2. How is GSM calculated?

GSM could be calculated in different ways. But the most commonly used calculation system is “GSM Cutter Machine.” Through this machine, five different samples of the same fabric are examined, and the mean value is multiplied with 100, and the result is the GSM, which is in oz/yard². We have described the process in detail above.

3. What does 300 GSM mean?

It simply means one square meter of that fabric weighs 300 gm. We know that higher GSM fabric is substantial, and lower GSM fabric is lightweight.

According to the GSM value, the fabrics are generally categorized in the following ways –

30 to 150 GSM is lightweight; 150 to 350 GSM is the medium or standard value;

More than 350+ GSM is known as heavyweight or more substantial fabric.

4. What is the Standard GSM value for a plain T-Shirt or printed T-Shirt?

180 GSM is the standard value for this type of T-shirt. But during summer there are lots of T-Shirts whose range is 130 to 150.

5. What is the best GSM for T-shirts?

Though it depends on our choice but the best one is in the range of 150 to 200 for T-Shirts.

6. Is thread count and GSM the same?

Thread count is also known as TPI, which is Threads per inch. Horizontal and vertical thread per square inch. Like the GSM here, also higher thread count means the coarser fabric and lower thread count means the finer one.

7. Why GSM is a crucial term when looking for a specific fabric?

It’s vital because the weight of the fabric depends on this value. The higher the GSM of a fabric is the higher the weight. Thus, if two fabrics are composed of the same material, than the one that has a higher GSM value will cost you more. It’ll be thicker also.

8. What GSM of fabric is best for embroidery?

It totally depends on the project at hand. Tightly constructed dense fabrics are typically considered to be the best fabric to embroider on.

Hopefully after reading this article, now you have a clear idea of what is fabric gsm and how you can calculate it. Remember you can also calculate GSM by using DIY fabric cutters and the described formula.

References