Basic Stitch and Seam Types : Become a Crafting Ninja

Seam vs Stitch

Stitch and seam both are directly related to each other. Sometimes we get mixed up with them. First, let’s know what stitch and seam are.

Stitch is produced by sewing a loop or unit in the seam line. One or more threads or loops of threads form stitches. The seam is a joint where two or more plies are held together. The main thing is, the seam can not be held without a stitch, and the stitch is produced in the seam line.

Now, we will know in detail about stitch types and then seam.

Basic Stitch Types

Before getting to types, let’s talk about the objectives first.

The Objective of Stitch

- Mainly stitch converts cut panels into garments.

- Attaching trims in garments

- Decorative purpose

Stitch Classification

- Class 100 – Single Thread Chain Stitch

- Class 200 – Hand Stitch

- Class 300 – Lock Stitch

- Class 400 – Multi Thread Chain Stitch

- Class 500 – Overlock Stitch

- Class 600 – Covering Stitch

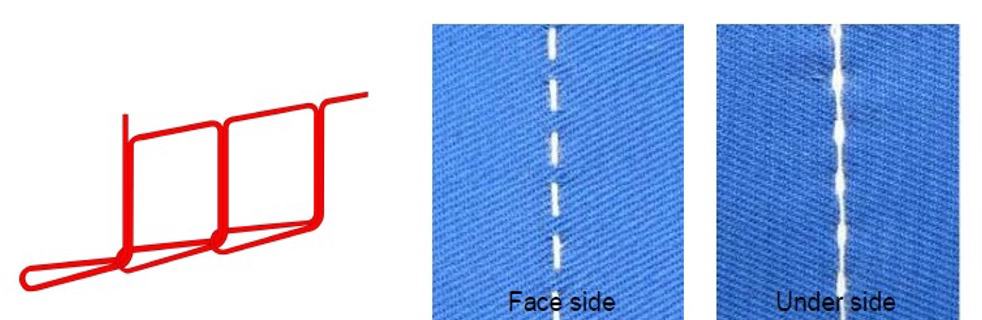

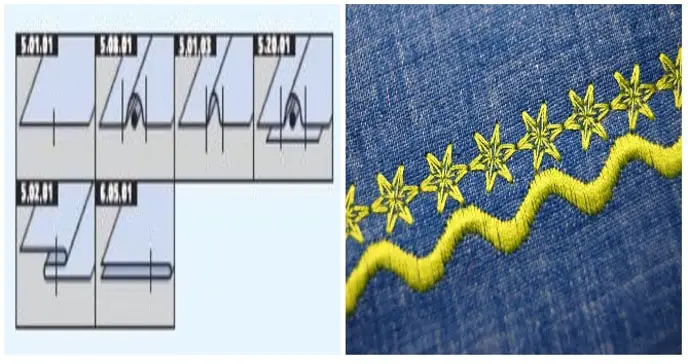

1. Class 100: Single Thread Chain Stitch

- Construction: Only one sewing thread introduced by the needle forms a single-threaded chain stitch. After passing through the fabric, the needle thread forms a needle loop, and the next loop from the same Thread secures it.

- Use: Temporary stitch, False stitch.

- Disadvantage: It tends to run back grom its finishing end.

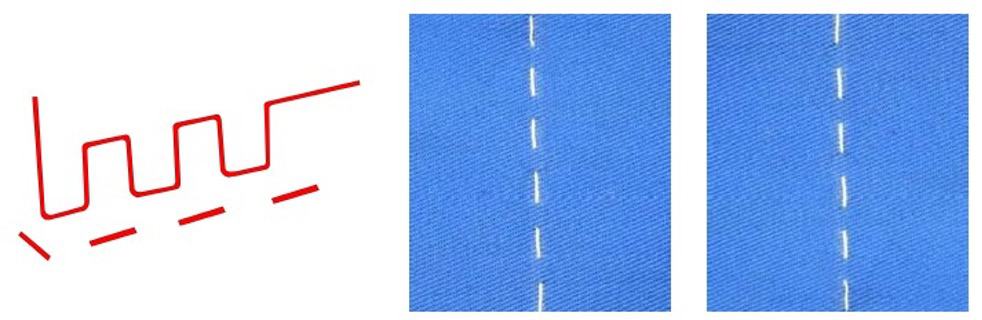

2. Class 200: Hand Stitch

- Construction: Only one sewing thread produces a hand stitch. A single line of Thread secures the stitch in and out of the garment.

- Use: Sample dresses, costly dresses, jackets.

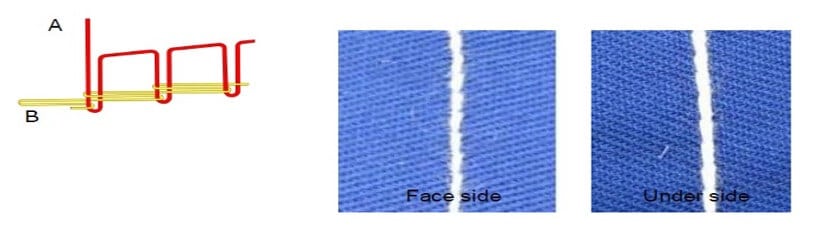

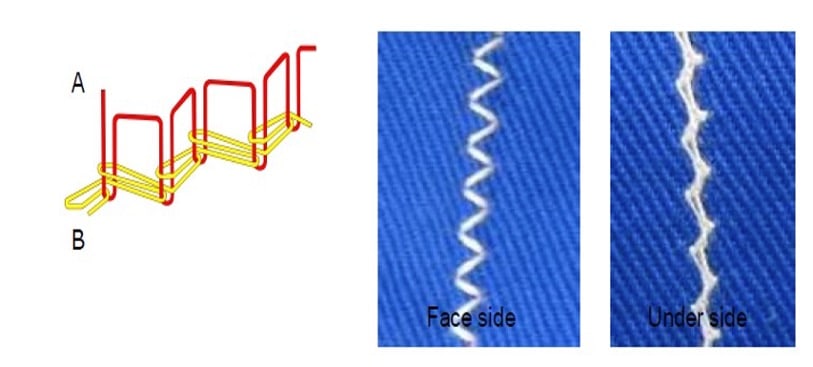

3. Class 300: Lock Stitch

- Construction: Two threads from lock stitch, i.e., Needle thread (A) and bobbin thread (B). After passing through the material, the needle thread interlaces with the bobbin thread.

- Appearance: Same appearance on both sides.

- Use: Placket topstitch, pocket topstitch, etc., also employed in a tactical vest sewing machine

- Disadvantage: The stitch is solid and tight but very low elongation and productivity.

4. Class 400: Multi Thread Chain Stitch

- Construction: Two threads from multi-thread chain stitch, i.e., Needle thread (A) and looper thread (B). After passing through the material, the needle thread interlaces and inter-loops with the looper thread.

- Use: Armhole topstitch, Neck topstitch; also useful in a sewing machine for outdoor gear

- Types:

Stitch Class 401

Stitch Class 404 – Zigzag chain Stitch

Class 500: Overlock Stitch

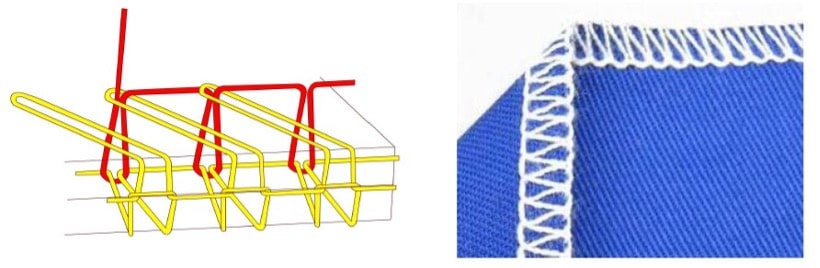

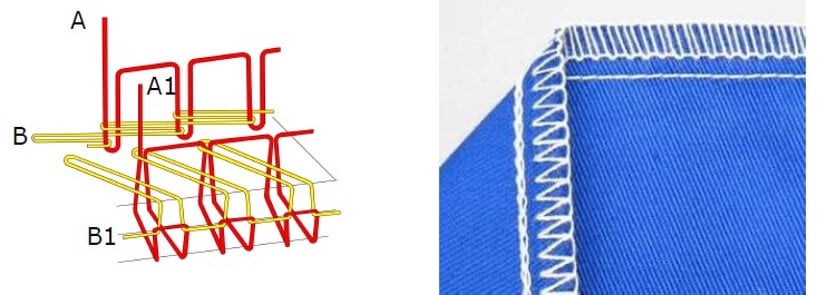

Stitch Class 504 – Three Thread overedge

- Construction: 3 threads form Three Thread Overedge stitch, i.e., one needle thread and two looper thread.

- Use: Neck Joint.

- Advantage: Higher productivity due to high machine speed.

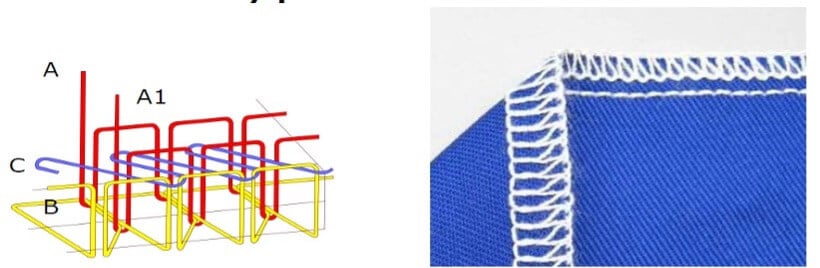

Stitch Class 512 Four Thread Overlock Stitch

- Construction: 4 threads form Four Thread Overedge stitch, i.e., two-needle Thread (A) (A1), an upper looper thread (C), and a lower looper thread(B).

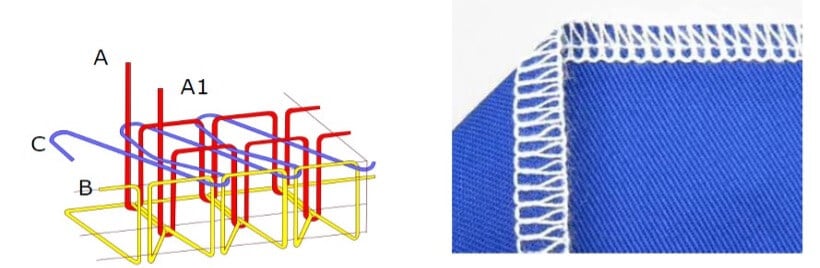

Stitch Class 514 Four Thread Overlock Stitch

- Construction: 4 threads form Four Thread Overedge stitch, i.e., two-needle Thread (A and A1), an upper looper thread (C), and a lower looper thread (B).

- Use: Side seam, Sleeve joint.

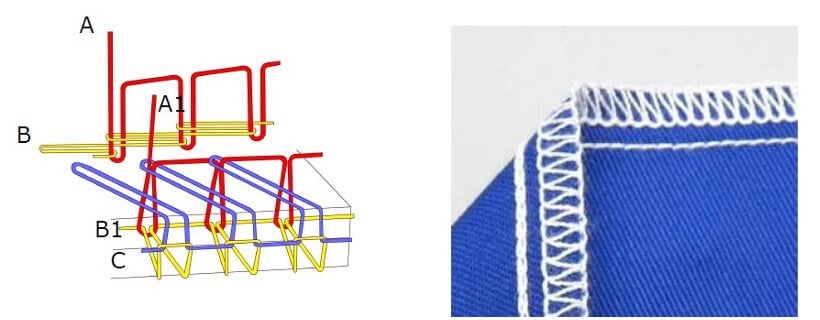

Stitch Class 515 Four Thread Overlock Stitch

- Construction: A stitch of stitch class 401 (A and B) at a specific distance from the edge simultaneously with a stitch of stitch class 503 (A1 and B1) on the edge of the material form this stitch class.

Stitch Class 516 Four Thread Overlock Stitch

- Construction: A stitch of stitch class 401 (A and B) at a specific distance from the edge simultaneously with a stitch of stitch class 504 (A1, B1, and C) on the edge of the material form this stitch class.

- Uses: Side seam and inseam of denim pants.

Class 600: Covering Stitch

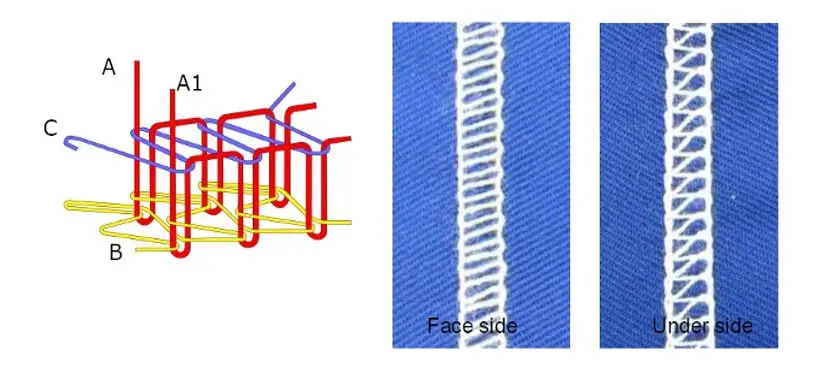

Stitch Class 602

- Construction: Four threads form the covering stitch, i.e., two-needle Thread (A and A1), one covering thread (C), and one looper thread (B)

- Use: Bottom hem, Sleeve Hem.

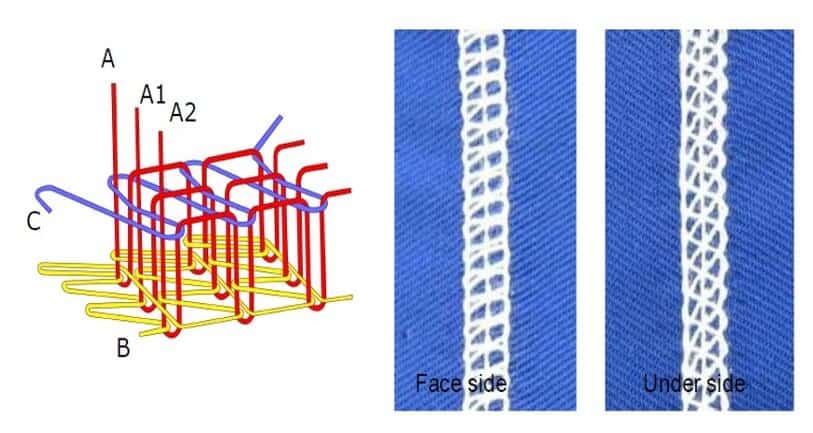

Stitch Class 605

- Construction: Five threads form the stitch class 605, i.e., three-needle thread (A, A1, and A2), one covering thread (C), and one looper thread (B).

Basic Seam Types

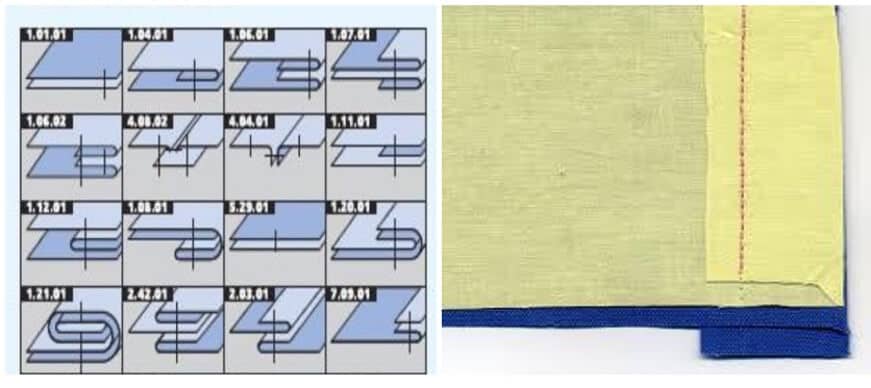

Seam Classification

There are six different classes of seam

- Class 1 Superimposed seam

- Class 2 Lapped seam

- Class 3 Bound seam

- Class 4 Flat seam

- Class 5 Decorative seam

- Class 6 Edge finish seam

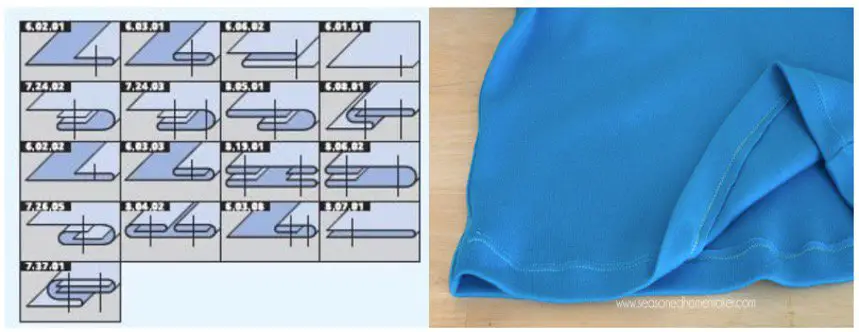

Class 1: Superimposed Seam

- Construction: Generally, two or more plies of material are overlaid over each other and then joined with one or more than one row of stitches near the edge.

- Use: Placket

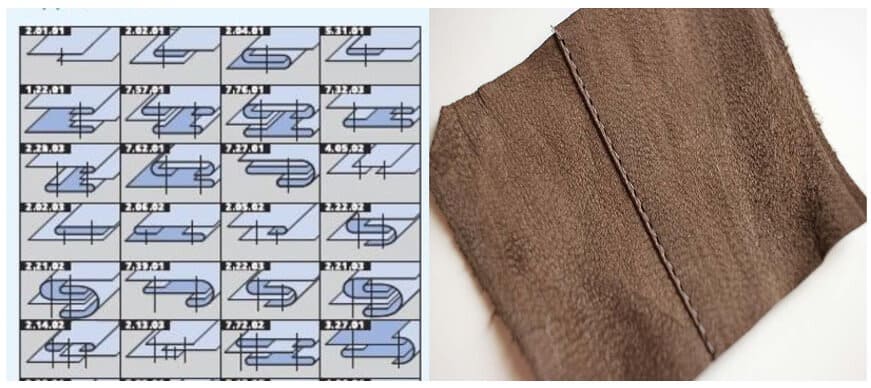

Class 2: Lapped Seam

- Construction: Generally, two or more plies of material lapped, i.e., with edges overlaid, folded, or plain, and then joined with one or more than one row of stitches. Minimum 2 components are required. Depending on the number of rows of stitching, there are different varieties of this seam.

- Use: Side seam, front rise/back rise in denim pants.

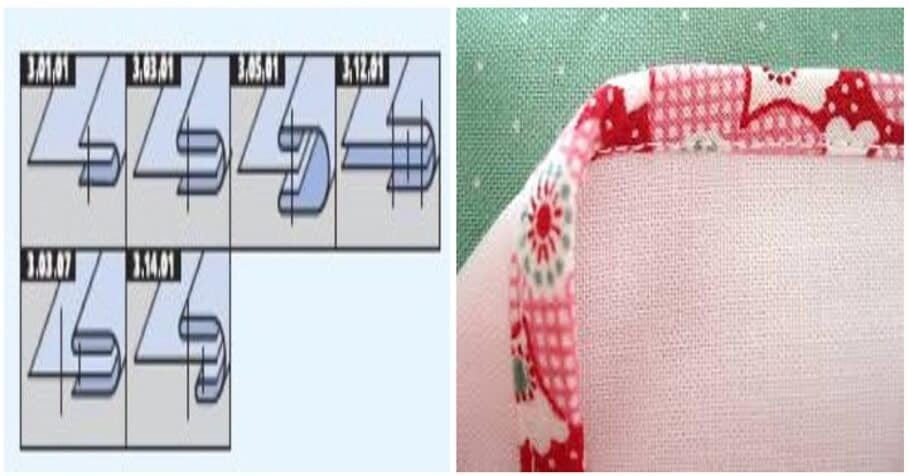

Class 3: Bound Seam

- Construction: Generally, a strip is folded to create a binding over the edge of the plies, and then both edges of the binding are joined with one or more than one row of stitches. This seam produces a neat edge on a seam exposed to wear of to view.

- Use: Neck Piping.

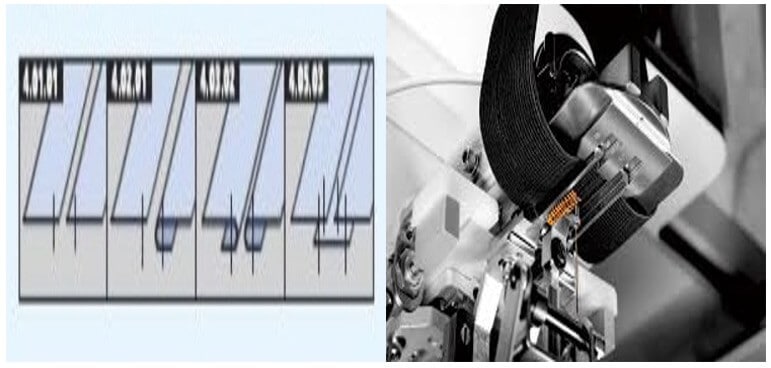

Class 4: Flat Seam

- Construction: Edge of two fabrics are brought together and oversewn with stitches to form this seam. As the edges do not overlap together, this is known as a flat seam.

- Use: Elastic edge joint – pretty useful in a sewing machine for stretchy fabric.

Class 5: Decorative Seam

- Construction: This is an ornamental stitch. Generally, this is a series of stitches curved or straight based on the design of a single ply of the material. It may include different forms of piping to create a complex design.

- Use: Embroidery

Class 6: Edge Seam

- Construction: This is formed by folding or covering the edge of the single ply of the material. Only one component is required for this seam.

- Use: Bottom Hem

Can Learning Basic Stitch and Seam Types Help in Quilt Making?

Learning basic stitch and seam types is crucial for anyone attempting a cutting sashing strips quilt tutorial. Understanding these techniques helps ensure precision and durability when piecing together the fabric. It also allows for more intricate designs and a polished finished product in quilt making.

Final Words

Hopefully, after reading this guide on the basic stitch and seam types, you’re well versed to complete any project whether it involves the hair sewing machine or the heavy fabric sewing machine.

REFERENCES