Pigment vs Dye | Pigment Dyeing | Classification of Pigments | Characteristics of Pigments

The word ‘Pigment’ is derived from the Latin word ‘pingue.’ It means ‘to paint.’

Pigments are one type of coloring material mainly recommended for light to pastel colors. They are molecular aggregates insoluble to the medium of application and use. So, the first question that tends to pop-up about pigment dyeing is,

What Are the Differences Between Pigment and Dye?

Here’s a summary of the difference between pigment and dye –

| Property | Pigment | Dyes |

|---|---|---|

Solubilty | Insoluble | Soluble |

| Particle Size | Bigger | Smaller |

| Affinity | No Affinity | Has Affinity |

| Application Form | Same as Original | Changed |

| Need of Binder | Necessary | Not Required |

| Surface Characteristic | Generally Harsh | Smooth |

| Effluent Load | High in Many Cases | Lower in Most Cases |

If you didn’t get the points, don’t worry! We have discussed them below in detail. Read on.

- Dyes are soluble in water or different solvents, but pigments are insoluble in water and most of the solvents.

- The particle size of the pigments is much bigger than that of the dyes.

- Mainly, pigments do not have any affinity towards textile fibers.

- Pigments are applied in their manufactured physical form (crystal structure and particle size distribution), but dyes are dissolved in water, and so their physical form is destroyed.

- Generally, pigment printed fabric delivers a harsh hand feel. Whereas, dyes give off smooth feeling surfaces.

- Metallic pigments, in particular, tend to be most detrimental towards the environment compared to its dye counterparts.

As pigments have no affinity towards fiber, they are held in the fiber surface with the help of binders. They form a film containing the pigments and adhesives, just like coating substances with paint.

You can also check this video –

https://www.youtube.com/watch?v=MD-OLSRgmWg

Physical Characteristics of Pigments

Size

The physical size of the pigments ranges from 0.01 micron-25 micron. Most commercial pigments ranger from 0.1-0.5 micron in size.

Shape

Pigments can be of different sizes.

- Spheroidal

- Cubical

- Nodular

- Acicular (needle-like)

- Lamelar (flakes)

Covering Power

The most crucial characteristic of pigment for application is its covering power. According to Euler’s rule, the covering power of pigments increases with the diminishing particle size until the value becomes of the same order as the wavelength of light absorbed or reflected. Translucency starts with a further increase in particle size.

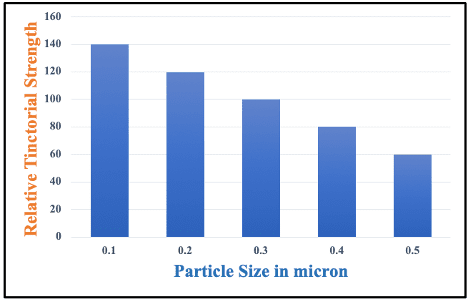

The critical point in the physical characteristic is that both the hue and the tinctorial strength of the pigments are affected by the size and shape of the pigments.

Another thing is that the properties of the pigments are vastly affected by a small change in the pigment manufacturing process.

The graph below shows the relation between particle size and the relative tinctorial strength.

Chemical Nature of the Pigments

Chemically, pigments can be classified into two categories.

1. Inorganic Pigments

The number of inorganic pigment are few. They are mainly used for metallic colors, white and black colors.

- The white pigments are Barium sulfate, zinc oxide, and titanium dioxide.

- Black pigments are manufactured from carbon black and Orion oxide.

- Metallic pigments are aluminum and bronze etc.

2. Organic Pigments

Organic pigments are abundant in number and varied in structure. Mainly organic pigments are used for textile applications. Organic pigment structures have azo, anthraquinone, indigo, thioindigo, phthalocyanine, and copper phthalocyanine.

The new classes of pigments fall into the following chemical structures.

- Quinacridone

- Dioxazine

- Perylene

- Perylene perinone

Classifications of Pigments

In the USA, pigment dyes are classified into four categories.

1. Pigments

They are full strength color free from all added dilutants. They are intrinsically or naturally colored and unaffected by alkali.

2. Toners

They are insoluble salts of acid and basic dyes. They exhibit some instability under alkaline conditions.

3. Lakes

They are similar to toners but precipitates in the presence of alumina and black fixer etc. The components are an integral part of the product.

4. Extended pigments

Pigments or toners are extended or diluted with the help of extenders such as alumina and black fixer, but they are not an integral part of the product.

In textiles, only pure pigments are used.

As binder is a must for using pigments, we should have basic knowledge about them.

They are film-forming substances composed of the copolymer. The copolymer contains a comonomer producing hard and soft homopolymer.

Binders must adhere to the textile substances. They should be stiff enough without being too flexible.

- Hard homopolymers are made by styrene, acrylonitrile, methylmethacrylonitrile, and vinyl acetate monomers.

- Soft homopolymers are made from butadiene and butyl acetate monomers.

Comonomer bearing reactive component is used to form a bridge between the binder molecules. They are known as the fixer. Generally, acrylamide and methyl acrylamide are used as reactive comonomers.

Pigment Dyeing

Pigment dyeing is actually known as pigmentation. It can be done in three ways.

- Mass pigmentation

- Exhaust method of dyeing

- Continuous dyeing by padding method

Mass pigmentation is only limited to the coloration of some synthetic fibers during their spinning from polymer to fiber.

Pigment Dyeing in the Exhaust Method

This method is seen in commercial garments dyeing. A modified laundry machine is used. The exhaust fabric dyeing method consists of four stages.

1. Fabric Cationization

After wetting the loaded garments in the machine, the cationic agent is added to the bath. The garments impregnated in the cationic agent solution gives the anionic pigment a slight affinity towards it.

It is done at 70°c for 20 minutes. Wetting agent to reduce the surface tension of water and acetic acid to control the pH are also used.

2. Pigment Exhaustion

The pigments are first mixed with water and dispersing agents, which gives a slight anionic charge to the pigments. Then the dispersion is gradually added to the machine bath. The temperature of the bath is slowly increased, and the machine is held at the dyeing temperature for at least 20 minutes. It is done to improve the adsorption of the pigment.

Exhaustion is done in 50-100°c for 10-40 min.

3. Binder Application

At this point, the binder is added to the bath. Then the garment is rinsed, and the machine is drained.

4. Drying/Curing

After the exhaustion of the binder into the garment, it is transferred into a commercial tumble dryer. Curing is carried out at high temperatures in acidic conditions.

Pigment Dyeing in Continuous Method

Pigment padding consists of passing the fabric through an aqueous solution of pigment and binder, mangling the fabric, and finally baking it. During the last step, the binder converts into insoluble form and holds the pigments with the fabric.

Drying temperature ranges from 90-120°C.

The fixation temperature depends on the nature of the binder. It generally ranges between 160-180°C.

Curing at 170°C for 90 seconds is usually enough. Afterwash is not required.

Reduction Clearing of the Dyeing Machine

- Reduction Clearing: It is done by using caustic soda and thiourea dioxide.

- Oxidation Process: Calcium hypochlorite followed by treatment with sodium bisulfate.

Commercial Names of Pigments and Binder

Pigments

- Aridye

- Acramin

- Helizerin

- Microfix

- Sherdye

Binders

- Helizerin

- Acramin

- Primal

- Perapret

- Neopralac

Advantages & Disadvantages of Using Pigments

There are several pros and cons when it comes to using these particles. Mainly, it depends on your preferred application. Take a look –

Advantages of Using Pigments

- Applicable to all kinds of fibers and fiber blends

- The full-color range is available

- Compound shades are produced with ease

- Easy shade matching

- Easy and cheap process

- Environment friendly

Disadvantages of Using Pigments

- Sometimes fastness to washing and rubbing is not so good

- Depth of shade usually limited to light to medium

- Make the fabric stiffer and so uncomfortable

That’s it, folks! I hope after reading this article you’ve gained enough knowledge to explain the difference between pigment and dye to others, as well as the pigment dyeing methods. Learning these basics in detail will help you understand the entry level t shirt printing machine easily. Stay safe! Additionally, understanding pigments and dyes will also help you make more informed decisions when choosing the best materials for your projects. Whether you’re working on fabric art or customizing apparel, knowing the difference can guide you in selecting the best paint for clothes to achieve vibrant, lasting results. Keep exploring, experimenting, and unleashing your creativity!

REFERENCES