Can You Dye Microfiber? – Problems & Possible Solutions

If I were to give you the simple answer, then YES, you can dye microfiber. But you have to remember that microfiber refers to the form of the material, not the material itself. What do I mean by that?

Generally speaking, any fiber which falls in the dimension of less than 1 denier or 1 dtex can be termed as microfiber. So, any material like polyester, nylon, polypropylene, etc. can be produced in microfiber form.

Therefore, the most accurate answer of the question can you dye microfiber would be –

If the material, which is used to produce the microfiber textile is dyeable, than that particular microfiber can be dyed.

Among all the fibers, polyester is the most preferred choice for producing microfiber and for good reasons.

Now, if you want to know why than you should read our previous post on microfiber.

Which Dye Should I Use to Dye Microfiber Materials?

The answer to this question lies in the material that was used to produce that microfiber textile. For example, polypropylene is undyeable because it’s non-polar, and no popular dye class has affinity for it . However, there are ways to modify it but we won’t discuss them here. Now, Polyester microfibers can be dyed with “Disperse Dyes. ” And Nylon microfibers can be dyed with “Acid Dyes. ” Polyester and nylon microfibers, therefore, exhibit excellent dyeing compatibility when paired with the appropriate dyes, allowing for vibrant and long-lasting coloration. However, mistakes or changes in design may require removing the dye, which can be achieved using the best fabric dye remover suited to the fiber type and dye class. Proper care and attention to the chemical composition of the remover ensure effective results without damaging the fabric.

Can You Tie Dye Microfiber

Without a doubt, you can!

If you’re trying to tie dye polyester microfibers then you should select the appropriate dye and process. And that appropriate dye would be disperse dyes. However, if you don’t like to invest much time in dyeing polyester microfibers, you can paint them also.

Let’s look at the methods one by one:

Tie Dyeing Microfiber (Polyester) with Disperse Dyes

In this method, you’ll have to impregnate your desired material in a boiling dyebath containing disperse dyes. In our tests, Jacquard IDYE-457 iDye Poly performed well among all the other fabric dyes.

You can mix your colors to get your desired shade by following the rules of color mixing. Or, you can achieve a multi-colored effect as well.

How to Tie Dye Microfiber Polyester and get Multi-colored effect?

You can achieve this by following these simple steps –

Multi-colored Tie-Dyeing of Microfiber

- Prepare individual dyebaths for each color.

- Tie dye the microfiber in the first dyebath in boiling temperature as instructed by the manufacturer.

- After completion, remove the rubber bands or whatever you used to tie it.

- Now, tie them again in a new pattern (whatever pattern you deem fit).

- Then, immerse them in the second dyebath containing a different color.

- Repeat the process if you want to add more color.

So, you may ask what is the mechanism behind this effect. Well, when you retie the fabric, the dye won’t be able to penetrate the tied portion. Thus, the previous color remains on that portion, giving you a multi-colored effect. However, you have to remember that, combined shades will start to develop from the third dyebath.

Tie Dyeing Microfiber (Polyester) with Crayons

This method is actually a printing method; ‘Transfer Printing” to be more precise. You have to get crayons that are transferrable to fabrics. With those, you can create your artworks on paper. Then, using a heat press machine or hand iron, you’ll be able to transfer the design to the fabric. Take note of the temperature requirement first.

Tie Dyeing Microfiber (Polyester) with Fabric Paints

This method has become very popular nowadays. The working principals are almost identical of printing. These paints are essentially a combination of pigments and a suitable binder. The binder acts as cross-linking agent, meaning bonds the pigments to the fabric. Thus, you don’t need to add any fixing agent(soda ash) or electrolyte (salt).

At first, you have to ensure that the fabric paint you get is compatible with synthetic fabrics. Then, you can either use the fabric as a canvas and draw your design on it using a brush, or you can immerse the fabric in the paint solution.

If you decide to go with the latter option, then dilute the solution first; otherwise, the high viscosity will result in uneven dyeing.

Problems Associated with Dyeing Microfiber

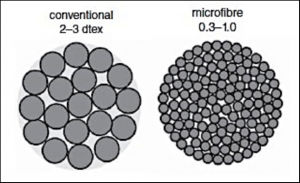

Microfibers tend to create a lot of difficulties while dyeing. That’s mostly attributed to their compact structure.

Conventional Fiber vs Microfiber

Here are the most pronounced ones –

- As there are a higher number of filaments in the same cross-section of microfiber, they have a very compact structure. So, the accessibility of dyes and dyestuffs is one of the major problems.

- Microfiber has a greater surface area that causes a higher rate of dyeing. So, un-levelness is another major problem.

- Lastly, microfiber exhibits lower wash and light fastness properties.

Possible Solutions for Dyeing Microfiber

The most challenging task is to ensure the levelness of the microfiber textile. Here are the most pronounced ones –

- Pre-setting can be done to improve the dyeing results. They also improve dimensional stability and softness. The main parameters of pre-setting are time, temperature, and tension.

- Treatment with concentrated alkali at higher temperature improves the accessibility of the dyestuffs. But, it reduces the weight and brings some changes in the properties of the fabric.

- Dyes with good migration, leveling, and fastness properties keep the un-levelness in control.

- A strong leveling agent, a higher quantity of dispersing agent, and a good anti-creasing agent can improve the dyeing properties.

- Proper after-treatment (soaping and reduction clearing) also improves the dyeing properties.

- Advanced dyeing machine having the ability to control the dosing and temperature gradient strictly is required.

Extra Tips to Ensure Level Dyeing of Microfiber Textile

Here are some pointers, which I found to be effective while dyeing microfiber textile –

- Firstly, a higher liquor ratio (1:20-1:30) should be maintained during dyeing.

- Secondly, a comparatively lower temperature (10-20°C lower than conventional) and temperature gradients should be maintained strictly during the dyeing.

- Finally, more holding time in the temperature must be ensured.

That’s it for now. I hope now you know the answer of can you dye microfiber.