Waterproof & Water Repellent Finishing in Textiles

When prevention from water penetration is the topic, three terms, water repellent, water-resistant, and waterproof, come into mind. So, what is the main difference between them?

- Water-resistant fabric can withstand light water, but if there is massive exposure of water on them, water will penetrate through the fabric.

- Waterproof fabric is impervious to water.

- Water repellent fabric falls in between the two. They are not easily penetrable. When a fabric is hydrophobic or repels water on contact, it is called water-repellent fabric.

How is a Water Repellent Finish Applied in Textiles?

The surface of the hydrophilic fabric is treated with wax materials such as paraffin or hydrophobic insoluble soap material such as Sodium Stearate to make it water-repellent. The process is:

First, the fabric is impregnated in a bath containing a soluble sodium soap solution.

Then, it is followed by impregnating the fabric in a second bath containing polyvalent metal salt that precipitates the hydrophobic soap in the fabric surface.

A combination of crease-resistant resin with paraffin is used to improve the permanency of the finish to subsequent washing.

If the emulsion of paraffin contains an anionic emulsifying agent, the addition of a polyvalent cation such as Al3+ prevents the repulsion of it with cotton’s negative surface.

Is Water Repellent Fabrics Air-Permeable?

Water-repellency is provided by a hydrophobic film on the surface of the fabric. There is still the presence of gaps as the interstices of yarn are not filled. So, they provide a certain degree of air-permeability.

Requirements for Introducing Water Repellency

What is Silicone Finish?

The modern water-repellent fabric is treated with an emulsion of polydimethylsiloxanes, which is called Silicone finish. Polysiloxanes are commonly known as silicones. They are available as liquids, rubbers, and solids.

The advantages are they spread very rapidly on the surface of the fabric and provides a softer handle along with water-repellency.

Partially polymerized methylselanols in an organic solvent or aqueous dispersion are mainly suitable for textile finishes. The degree of water-repellency depends on the orientation of the polysiloxane molecules on the surface of the fabric.

The methyl groups of silicone chains remain away from the polar fiber, and the oxygen atoms are oriented towards the fiber. The incorporation of zirconium or titanium compound presents an array of hydrophobic methyl groups on the surface of the fiber and provides water-repellency along with the softer handle.

Requirement for Applying Silicone Finish

The fabric must be free from surface active wetting agents so that good adhesion of silicone is possible. So, thorough rinsing of the fabric is necessary.

As previously mentioned that waterproof fabrics are impermeable to water, so they require a certain level of breathability. So, what is waterproof breathable fabric is an essential question.

They are a part of technical textiles and designed for protection against rain, wind, and loss of body heat. The main problem for protection fabrics was that they were very uncomfortable to wear. The reason behind this is that they were very stiff, and the perspiration vapor can’t escape through them.

Water vapor can passively diffuse through breathable fabrics, but still, they prevent the penetration of liquid water. The water vapor maintains the body temperature in contact with the skin.

There are three types of waterproof breathable fabric available.

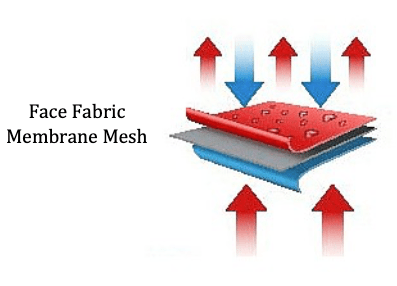

Construction of Waterproof Fabric

Multiple layers are combined in waterproof fabrics for stylish functionality.

- ‘The Face fabric’ usually made by Nylon or polyester with a coating of expanded PTFE is responsible for the protection and aesthetic properties.

- ‘The membrane’ keeps the water out, generally coated by Polyurathane.

- ‘A scrim or mesh’ is joined in the inner surface for comfortability. It is only available in 3 layer fabric. 2 layer or 2.5 layer fabrics have a separate lining.

Requirements for Producing Waterproof Fabric

- The seams should be sealed for additional protection against the water leakage. For this, a thin waterproof tape is sealed over the seams by heating.

Two types of garments are available.

- Fully sealed garments

- Critically sealed garments – Neck, chest, and shoulder areas are taped only.

- In the Durable Water Repellent method, the fabric is treated in a particular technique, which causes the water to bead up and roll off the fabric.

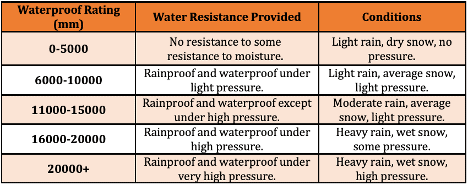

Rating System for Protection Against Water Penetration

The most renowned method is the ‘Static-column Testing Method.’ According to the process, a 1-inch×1-inch square tube is placed over the fabric and how high a column of water can suspend over it until the fabric gets leaked is determined in millimeters.

REFERENCES