Water Repellency Test of Fabric by Spray Rating Tester

Water repellency is a function of fabric that describes the resistance of the fabric to surface wetting & water penetration; in easy words, it measures non-spreading characteristics of water droplets on the material surface.

Usually, water repellency is gained by treating the material with paraffin, silicon, acid-based melamine, and fluro carbons. This function can be obtained by film coating or lamination. The main object of water repellency is to protect the textile material from getting wet in the case of water exposure.

AATCC Water Repellency Test of Fabric by Spray Rating Tester

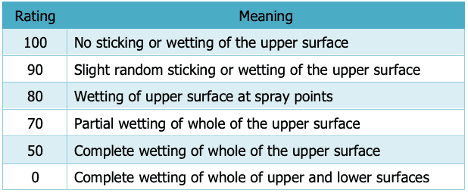

According to the “American Association of Textile Chemists and Colorists (AATCC),” a visual photographic chart should be used to give a rating on water repellency. Tested material’s final result is given by comparing the chart and appearance of the actual fabric.

Apparatus

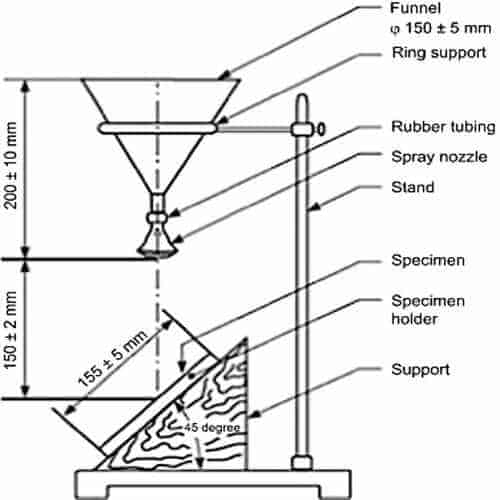

1. Spray Tester

2. Scissors

3. Fabric

4. Measuring cylinder

5. Thermometer

6. Water

Precaution

To carry out the test, water temperature should be accurate, and it should be at 700 F and should be poured steadily during the test. A bucket should be under the instrument to catch the water while testing.

Sample Preparation

The sample should be conditioned at least 4 hours in the STD testing environment and should be cut accordingly to fit it in the 6-inch diameter embroidery hoop, and we need to cut 5 samples.

Atmosphere

The standard atmosphere for testing should be maintained, because moisture content may change the weighting of the sample and jeopardize the result. So the temperature should be near 20°c ± 2°c and the humidity should be near 65% ± 2%.

Working Procedure

- At first, we should fix the fabric sample into the specimen hoop

- Then, specimen hoop should be placed into the instrument’s specimen area, which is inclined at an angle of 45°

- Now we fill up the measurement cylinder with approximately 250 ml of water and check the temperature to ensure if it’s in 750F.

- After that, we steadily pore the water at the top of the instrument, which looks like a funnel.

- When all the water is showered, the fabric specimen is observed and compared with the AATCC visual scale.

- In total, five tests are done, and the value is taken to the nearest rating since interpolation is prohibited. The data of tests are kept.

- The average is calculated from all the test data, and it’s our main result.

Standard Spray Test Rating

Remarks

This test is also known as AATCC test method 22, Water repellency-spray test. This method is technically equivalent to ISO 4920 and BS EN 24920.

This test is widely used in industries and laboratories to easily determine water repellency.

REFERENCES