Different Types of Dyeing Machines

It’s impossible to go over all types of dyeing machines in a single article in depth. Therefore, I will try to keep it short and precise while describing a textile dyeing machine. Basically, we can categorize the dyeing machines into four types.

- Fabric Dyeing Machine

- Lab Dyeing Machine

- Yarn Dyeing Machine

- Fiber Dyeing Machine

Let’s check out the distinct features and other attributes of the dyeing machinery.

1. Fabric Dyeing Machine

Jet Dyeing Machine

Features

In this type of dyeing machine, the fabric is dyed in rope form. The rope is passed through a pressurized nozzle, which continuously sprays dye liquor.

Application

This industrial dyeing machine is mainly used for dyeing polyester fabric.

Advantages

- This machine needs a low liquor ratio

- Fabric shows low crease formation

- Can dye in high temperature and pressure

- Lengthwise tension on fabric is less

- Need lesser time to dye

Disadvantages

- Fabric rope may be entangled

- Maintenance cost is high

- In the case of rope breakage, reloading rope is complicated

- Foam forming chemicals have to be avoided

- While dyeing accessibility is limited

Winch Dyeing Machine

Features

In this dyeing machine Fabric is dyed in rope form. The rope gain movement by a winch, which helps to rotate the fabric throughout the dye liquor .the winch pulls the rope from dye liquor and passes forward

Application

Used for all kinds of fabric

Advantages

- Operating method is simple and easy

- Lengthwise tension is less compared to jigger dyeing machine

- Any types of fabric can be dyed

- Can be used for desizing and washing

Disadvantages

- Every batch needs sewing and cutting for joining and cutting the rope.

- Need more time for loading and unloading

- Liquor ratio is too high

- Can’t dye in high temperature

- Need to operate under atmospheric condition

Beam Dyeing Machine

Features

Fabric or yarn is wounded on a perforated beam. Then the dye liquor is passed through the beam at high pressure from inside to outside or outside to inside.

Application

Usually used for automotive fabrics, nylon ballutes tricots, and acetates.

Advantages

- Can be dyed in high temperature and pressure

- Both yarn and fabric can be dyed

- Can work with low liquor ratio

Disadvantages

- Production time is high

- Uneven dyeing may occur

- Loading/unloading time is high

- Need extra mechanism for beam winding

- Need to operate under atmospheric condition

Jigger Dyeing Machine

Features

In this type of dyeing machine, the fabric is dyed mainly with two rollers. One roller let off the fabric and passes through the dye liquor, and at last, a take-up roller wounds the fabric.

Application

Mainly used for woven fabrics such as taffeta, poplin, satins, and plain woven fabrics.

Advantages

- The fabric is dyed in open width form

- Fabric remains dimensionally stable

- Need low liquor ratio

- Loss of heat and liquor is less

- Low risk of crease formation

Disadvantages

- Lengthwise tension on fabric is high

- Sometimes uneven dyeing occurs

- Washing off is a little bit tough due to the low liquor ratio

- May cause yarn breakage on the fabric due to over tension

Solvent Dyeing Machine

Features

In this type of dyeing machine, the fabric is loaded on a drum, and the drum rotates. while rotating solvent/liquor is spread on the fabric.

Application

Mainly used for dyeing polyester.

Advantages

- Water usage is too much low

- Need less time

- Solvent can be recycled

- Saves energy for heating

- Even dyeing throughout the fabric

Disadvantages

- Raw material for dyeing is expensive

- Need different types of extra mechanism

- Can’t be used for all types of fabric

- Need skilled manpower

Padded Mangle Dyeing Machine

Features

In this type of dyeing machine, the fabric is passed through the dye liquor, and with the help of rollers. Then it’s passed through a pair of rollers that works as squeezing roller. After that, the fabric is steamed, and curing is done.

Application

Used for both cellulosic and manmade fibers.

Advantages

- Done on a continuous process

- Need less time

- Wash off can easily be done

- Can be used to serve different wet process operations

Disadvantages

- Batching is complicated

- Need high liquor ratio

- Batch to batch shade variation occurs

- Uneven dyeing occurs

- Need high manpower

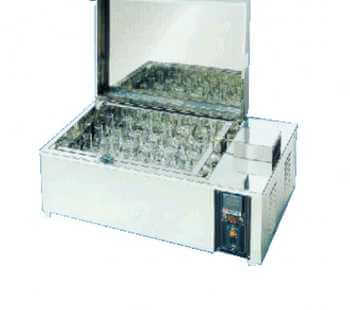

2. Lab Dyeing Machine

IR Beaker Dyeing Machine

Features

Fabric and yarn both can be dyed in swatch form/loose stock form. Uses an enclosed dyeing mechanism. Temperature is risen by infrared radiation.

Application

Used as a yarn and fabric sample dyeing machine.

Advantages

- Easy and user-friendly

- Loading and unloading is easy

- Can dye in high temperature

- No pressure leakage

- Can dye in low liquor ratio

- Need lesser time for dyeing

Disadvantages

- Limited amount of samples can be dyed

- Power consumption is high

- Maintenance cost is high

Jigger Lab Dyeing Machine

Features

Fabric can be dyed in rope form. Uses open dyeing mechanism

Application

Used for all kinds of fabric.

Advantages

- Can dye as actual jigger machine

- Actual rope tension can be used

- Rotation value can be used

- Can dye in a low bath ratio

Disadvantages

- Can’t be used in high temperature

- The operation procedure is complicated

Oscillating Lab Dyeing Machine

Features

Both fabric and yarn can be dyed in swatch form/loose stock form. Uses an enclosed dyeing mechanism

Application

Used for every kind of fabric and yarn

Advantages

- Dyeing time is low

- No pressure leakage

- Can dye in low liquor ratio

Disadvantages

- Can’t dye in high temperature

- Power consumption is high

- Loss of heat is very often

3. Yarn Dyeing Machine

Package/Cop/Cheese Dyeing Machine

Features

Yarn is wound on perforated plastic/steel bobbin and dyed in a cage with a continuous flow of liquor.

Application

Every type of yarn can be dyed. They are dyed in cheese, cone, and linear cylindrical packages.

Advantages

- Can be dyed in low liquor ratio

- Yarn transportation is easy

- Can dye in high temperature

- Fully pressurized dyeing

Disadvantages

- Need extra machines for back process and after process

- Uneven dyeing may occur

- Fastness properties are a big issue

Hank Dyeing Machine

Features

Hanks of yarn are hanged on a beam and dyed with a continuous flow of liquor.

Application

Almost every type of dye classes can be used by this machine.

Advantages

- Yarns can directly be dyed

- Yarns are dyed in atmospheric condition

- Machine price is low

- Same liquor can be used for different batches

- Operation module is easy

Disadvantages

- Every batch needs sewing and cutting for joining and cutting the rope.

- Need more time for loading and unloading

- Liquor ratio is too high

- Can’t dye in high temperature

- Need to operate under atmospheric condition

Warp Dyeing Machine

Features

The yarns are converted into a rope, and that rope is wounded on a perforated warp beam. The wounded beam is called a ball package, which is dyed in an enclosed system.

Application

Only used for cotton fabric, especially for denim manufacturing.

Advantages

- Production is high

- Need less time

- Can dye in high temperature

- Can dye in high pressure

- Need less liquor ratio

- More economical

Disadvantages

- Uneven dyeing may occur

- Loading/unloading time is high

- Need extra mechanism for beam winding

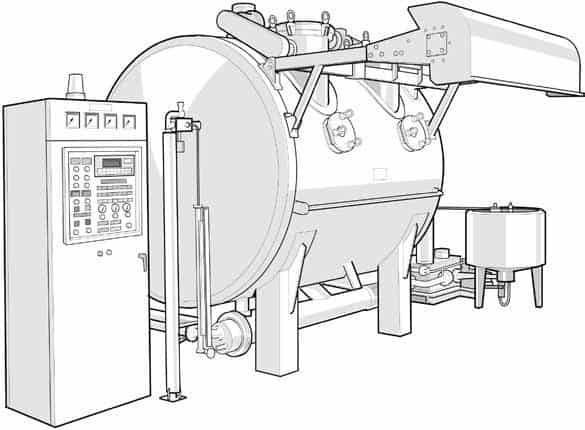

4. Fiber Dyeing Machine

Continuous Loose Stock Dyeing Machine

Features

Fibers are dyed in an enclosed chamber step after step. The fibers stay stationary, and the liquor moves around throughout the fibers.

Application

Used for cotton and wool fibers.

Advantages

- Can be dyed in high pressure

- Need low liquor ratio

- Can dye in high temperature

- No wastage of fibers

- Big batches can be dyed in once

Disadvantages

- Maintenance cost and time is high

- Economically not profitable

Discontinuous Loose Stock Dyeing Machine

Features

Fibers are dyed in an open system.

Application

Used for cotton and wool fibers.

Advantages

- Dyeing and pretreatment can be done in separate chambers

- Big batches can be done easily

- Proper level dyeing is possible for the whole batch

Disadvantages

- Dyeing time is high

- Need close supervision

- Rate of wastage is high

In case you’re wondering, we’ve already gone over the different types of fabric dyeing machines. If you’re interested check it out. And if you’re eager to learn about the continuous dyeing process, then we’ve got you covered too.

That’s all for today! I hope you’ve learned the basics of different types of dyeing machines.

REFERENCES