How to Dye Acrylic Yarn and Fabric

If you want to dye acrylic at home, that will not be a good idea. The acrylic dyeing procedure is not as easy and safe as wool dyeing. For absolute beginners who are looking for a one-time solution, I always suggest them to select the best paint to use for clothes rather than dyeing it. I will discuss how to dye acrylic later. But first, let’s learn something about acrylic fiber.

What is Acrylic Fiber?

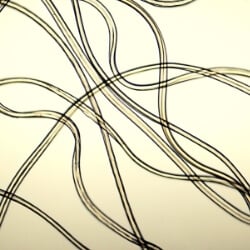

It is an important synthetic fiber produced from polyacrylonitrile by addition polymerization in which the monomer is acrylonitrile.

Commercially, most of the acrylic fibers are copolymers of acrylonitrile and monomers of vinyl compounds, for example, vinyl alcohol, acrylic acid, vinyl chloride, vinyl acetate, methacrylic acid, methacrylate esters. It is done because homopolymers are very difficult to dye. The acrylic fiber is negatively charged.

Classification of Acrylic Fibers

According to the definition, they can be divided into two.

- Acrylic fiber: Contains at least 85% of acrylonitrile by weight in the copolymer.

- Modacrylic: Contain at least 35% of acrylonitrile but less than 85% by weight in the copolymer.

Commercially, acrylic fiber is found in the name of Acrilan, Orlon, Dralon, Courtelle, Nitron, and Leacryl.

Acrylic fiber possesses the least breath-ability, so they are very much preferred for heat-retention garments.

Acrylic fiber is commonly used in sweaters, hoodies, gloves, athletic wear, carpeting, boot lining, blankets, upholstery, etc.

Two types of dyes can be used for acrylic dyeing.

| Disperse Dyes | They exhibit low affinity towards the fiber and only suitable for pale to medium shades. |

| Basic Dyes or Cationic Dyes | The most widely used and suitable type of dye for acrylic dyeing is basic/cationic dye. They can produce dark and deep shades exhibiting great fastness properties. |

The dyes that work for natural fibers will not work on acrylic as it is completely made of synthetic material. All-purpose dyes will not work. Also, fiber reactive dyes will not work too along with acid dyes. They will be washed away leaving a temporary stain.

Acrylic Dyeing with Disperse Dyes

Now, if you want to dye at home, I will suggest you to use disperse dyes rather than basic dyes. You can ask me why?

Firstly, the acrylic dyeing procedure with disperse dyes is easy and simple. The process is as follows –

- Pre-wash the material to be dyed for smooth uptake of the dyes.

- Heat the dyes mixed water in the dye-pot and completely dissolve the disperse dyes.

- Add the acrylic material to be dyed.

- Heat dye dyebath to boil for around 30 min or so.

- Let the dyebath to cool, occasional stirring is necessary

- Drain and rinse the material in hot water.

- Wash the material to remove the access dyes from the surface.

Secondly, disperse dyes are reasonably non-toxic whereas basic dyes are not.

But, there is a major disadvantage of using disperse dyes. And that is the fact that you can not produce intense and deep colors.

Some Important Instructions for Acrylic Dyeing

- iDye Poly is a suitable commercial disperse dye for acrylic. It can be dissolved directly in water easily by stirring. If you use other brands, filter the dissolved dyes through nylon stroking to make sure there is no undissolved dye remaining.

- Don’t get yourself confused with iDye poly and plain iDye. iDye poly contains disperse dyes, so it will work on acrylic but plain iDye is a direct dye and so it will not work on acrylic.

- You don’t need to use the color intensifier or carrier provided by the dye supplier because it does not affect acrylic dyeing. It will only work on polyester dyeing.

- If you use Aljo Mfg dyes for your acrylic dyeing, you must follow their instructions. Their dyeing process is different from the high energy disperse dyes dyeing process.

Acrylic Dyeing with Basic Dyes

If you want to produce deep colors such as black, navy, etc., what will you do?

Then, you must use basic dyes. Let’s talk about the steps for dyeing acrylic yarn or fabric with basic dyes.

- Paste the dyes using acetic acid.

- After adding hot water, boil the dye until the dyes are fully dissolved.

- Dyebath preparation with retarder, sodium acetate as a buffer. Dyeing around pH 5 will help to control the dyeing rate. The retarder is necessary for level dyeing.

- Immerse the fabric in a blank dye bath containing the retarder at 40◦C for 10-15 minutes.

- Add the previously dissolved dye.

- Slowly increase the temperature to boil.

- Continue dyeing for about an hour.

- After completion of the dyeing, slowly cool the dyebath to 50-60◦C to avoid the immediate setting of creases in the fabric.

- Wash in water and then with soap to remove the excess dyes and chemicals.

The following question may come into your mind.

Why Dyeing with Basic Dyes Give Acrylic Good Wash Fastness

I am answering this ques with the mechanism of the dyeing. It is a three-step dyeing.

- First, the colored cations of the basic dyes (ionized) are absorbed on the acrylic fiber surface. This is actually known as adsorption.

- Then, they get diffused into the fiber interior at the dyeing temperature.

- Strong electrostatic attraction retains the dye cations in the fiber substance.

Due to this strong bond, they show great wash fastness properties.

The main disadvantage of basic dyes is their toxicity. Some basic dyes are carcinogenic. If you have to use basic dyes you must follow the safety precautions provided by your dye supplier. Another thing is that basic dye may color your dye-pot and anything they get in contact with.

Precautions for Acrylic Washing

Washing is a very critical stage in acrylic fiber dyeing. You should adhere to the following washing instruction for acrylic dyeing.

Wash with Warm Water

You should keep in mind that both hot and cold water may harm the acrylic fabric. Washing acrylic with warm water is most preferable. Washing in cold water may make the fabric inflexible and firm. Washing in hot water may damage and melt the fabric.

Don’t Wash with Differently Colored Fabrics

Acrylic fabrics are prone to pilling more than other fabrics. So don’t wash your acrylic fabric or garment with other fabrics that don’t have the same or a quite similar color. Otherwise, your fabric will be covered in pills.

What is the Use of Retarder in Acrylic Dyeing

Uneven dyeing may occur if the initial exhaustion of the dye molecules is uneven. So, it is very important to control the initial rate of exhaustion/strike of the dye molecules. This is done by the retarder.

Two types of retarders are available.

1. Cationic Retarder

They tend to retain the dye molecules in the dyebath at the initial stage of dyeing by creating a complex with them.

2. Anionic Retarder

In the ion-exchange dyeing process, the anionic retarder competes with the dye molecules for the ionic sites in the fiber at the initial stage of dyeing.

A suitable retarder will provide uniform level dyeing along with allowing the full saturation of the dyeing.

Final Words

As you have probably noticed by now, disperse dyes are the best choice for dyeing acrylic because of its easy application process and non-toxic nature. Whereas, basic dyes should only be selected when you need to dye deep shades and toxicity isn’t a concern for you.

Well, that’s all for this post. We hope now you know how to dye acrylic yarn or fabric with both disperse and basic dyes.

REFERENCES

- Shore, J., & Society of Dyers and Colourists (Eds.). (2002). Colorants and auxiliaries: organic chemistry and application properteis. Vol. 1: Colorants (2. ed.). Bradford, West Yorkshire: Society of Dyers and Colourists.

- Broadbent, A. D. (2001). Basic principles of textile coloration. Bradford, West Yorkshire: Society of Dyers and Colourists.