What’s the Difference Between Mordants and Other Chemical Assistants Used in Dyeing?

Mordants are metal ions that facilitate the bonding of the natural dyestuffs to the fiber. Generally, the molecules of the natural dyes will not adhere to the fiber without the help of mordants. Initially, you may get a beautiful result, but it will be washed out or faded away soon.

Soda ash, vinegar, or salts are not mordants. Most of the dyes that create physical and chemical bonds with the fiber do not require any mordants.

Soda ash is an auxiliary chemical in dyeing. It is generally used to achieve a high alkaline pH during dyeing with fiber reactive dyes. A cellulosate ion forms in the fiber at high pH, and it can attack the dye molecules and form a strong covalent bond.

A lower pH is required for dyeing protein fibers such as wool or nylon with acid dyes. Acids such as citric acid or vinegar are used to achieve this lower pH. Although those acids are not mordants, some chemical such as tannic acid is a mordant having acid in their names.

The Function of Mordants and Different Mordants

Natural dyes have no affinity towards fibers. The attachment of the dye molecules is obtained by metal ions called mordants. Most of the natural dyes and very few synthetic dyes are mordant dyes.

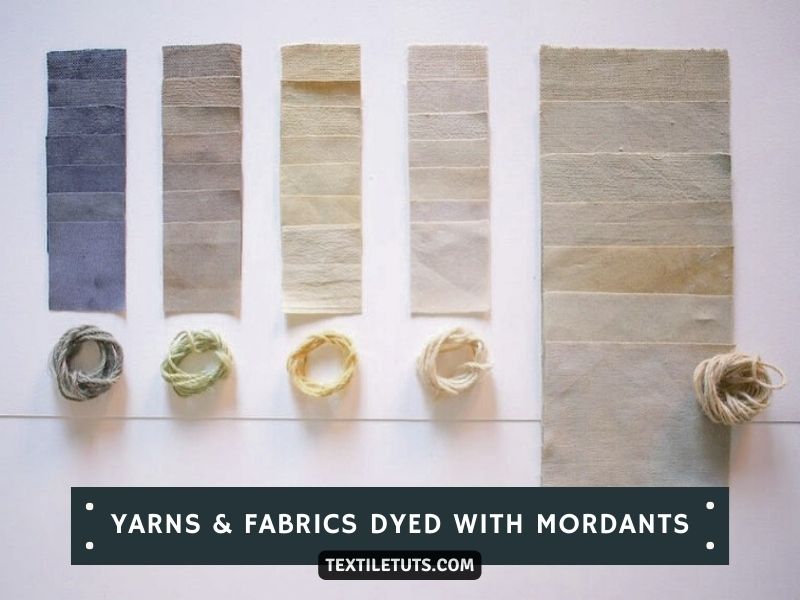

Alum, chromium, copper, tin, and iron are the most common mordants. The problem is some of the mordants are toxic and hazardous. They cause environmental damage. Now, let’s talk about some mordants.

Alum

Alum is chemically known as potassium aluminum sulfate, the most popular mordant due to its availability and easy usability. Dyeing and mordanting can be done at the same time. You have to mix alum in your dye bath and then add the materials to be dyed.

Alum is the safest option you have among the mordants available. Great use of alum can make your yarn or fabric sticky. Experiments should obtain the optimum level.

Iron

If you want lovely brown colors, iron is a suitable mordant. Free and effective iron mordant can be obtained by boiling old nails in water. The colors will become dull due to this mordant. Fifteen grams of iron per 500grams of fiber is recommended.

Copper

Now, if the requirement is to produce a lovely green color, choose copper. They are chemically found as copper sulfate. Old pennies are made of copper, and so you can use them as mordants.

The measurement of using copper is the same as iron. As copper is toxic, careful use is recommended.

Tin

Careful use of tin is required as they tend to be harsh on wool and can make wool brittle. Generally, a small amount is recommended. The main advantage is, tin makes a very bright, clear, and fast color. It is used in a small amount with other mordants. Sometimes tin is used to brighten the colors as an afterbath.

Chromium

2-4% o.w.f chrome generally recommended for wool. The softer handle of wool is not affected by chrome, and that’s why it is preferred over others sometimes. But the main problem is, they are the most hazardous. The hexavalent ion of chromium (in potassium dichromate) is known as carcinogen.

Important Notes

As the dyers become conscious about health and environment during recent years, the use of mordants is reduced. They may cause irritations and health problems.

Proper safety gloves and equipment should be used during measurement and dyeing. A well-ventilated area is recommended. The safe disposal of the dyes and mordants are also required.

Mordanting Process

The protein fibers such as silk and wool require a plant extract(natural dye) and mineral mordant for dyeing. The natural dye extract will be fixed into the wool if the mordant is added and stirred well in the dyebath during dyeing.

The general process is, adding a suitable mordant in water and stir until the mineral is dispersed fully in the water. After that, slowly heat the dye bath with the wool for 20-30 minutes and then allow it to cool. During the cooling period, the mordants will get inside the fiber in the bath. You can dry the material and store it for future use. Also, you can use natural dyes in another bath and dye the material.