Swelling of Textile Fibres

What is Swelling

When a fibre absorbs water, they change in dimension(length, width). The dimensionally changes that takes place due absorbing of water or moisture by any fibre is called ‘swelling’. It may occure length-wise or width-wise.

Significance of Swelling

The predominant width-wise(transverse) swelling results in a shrinkage of twisted or interlaced structure.

The closely woven fabrics will be completely blocked when the fabrics are swollen, and they may be impermeable to water. Thus, this property of fibre is used to make waterproof fabric.

It is also an important factor in crepeing due to increased twist angle in swollen yarn, and in drying and dyeing.

Types of Swelling of Textile

This phenomenon may be classified in terms of increase of the folowing criterias:

- Transverse diameter

- Axial

- Transverse area

- Volume

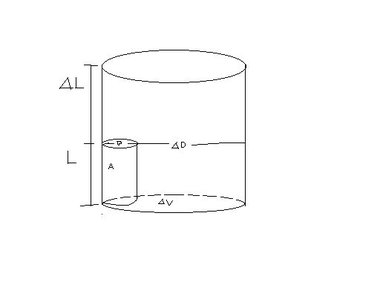

Transverse Diameter Swelling

Fractional increase in diameter of a fiber after swelling is called transverse dia swelling(SD.mathmatically,

SD = ∆D / D ;where,

- D = original dia

- ∆D = dia of swollen fibre

Axial Swelling

Fractional increase in length of a fiber after swelling is called axial swelling(SL.

SL = ∆L / L; where,

- L = original length

- ∆L = swollen length

Transverse Area Swelling

Fractional increase in area of a fiber after swelling is called transverse area swelling(SA.

SA = ∆A / A ;where,

- A = original area

- ∆A = area of swollen fibre

Volume Swelling

Fractional increase in Volume of a fiber after swelling is called transverse area swelling(SV.

SV = ∆V / V ;where,

- V = original volume

- ∆V= volume of swollen fibre

What is the Reason Behind Swelling of Textile?

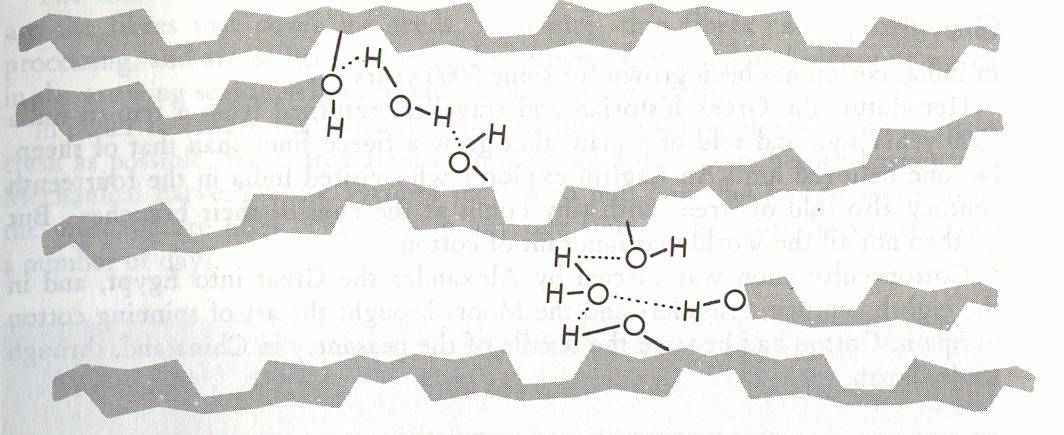

We know, a fibre is consisted of polymer chains. This chains are arranged differently in different regions. The region having parallel arangement of chains are called crystalline regions and disoriented region is called amorphous region.

This polymer chains have empty spaces among them, known as the ‘molecular space’. When a fibre is immersed into water, water molecules enter into these spaces and pushes the fiber chains. As a result, Swelling occures.

Water Penetration During Swelling

More orientation means less Swelling, and vice-Versa!

In a highly oriented fibre, the moleculear chains are lying parallel to the fibre axis. Which results in low molecular space, so swelling will be lower

For the same reason, less oriented fibre has high swelling, because they have high molecular space for water molecules to enter!

That’s why Viscose swelling is greater than Nylon swelling, cause Nylon is much more oriented than Viscose.

Relation Between Transverse Area Swelling and Transverse Dia Swelling

For a circular fiber,

Area A = (π/4)D2

For a swollen fiber, we get, A+∆A = (π/4)(D+∆D)2

= (π/4)(D2 + 2D. ∆D + ∆D2)

Now,

SA = ∆A / A

= (A+∆A-A) / A

= {(π/4) (D2 + 2D. ∆D + ∆D2) – (π/4) D2}/ (π/4) D2

= (π/4) (D2 + 2D. ∆D + ∆D2 – D2) / (π/4) D2

= (2D. ∆D + ∆D2) / D2

= (2D. ∆D / D2) + (∆D2/ D2)

= 2(∆D / D) + (∆D2/ D2)

= 2 SD + SD2

So, SA = 2 SD + SD2

Relation Between Area, Volume, and Axial Swelling

For a circular fiber,

Volume, V=AL

For a swollen fiber, we get,

V +∆V = (A +∆A )(L +∆L)

= AL + A∆L + ∆AL + ∆A ∆L

Now, SV = ∆V / V

=(V+ ∆V – V) / V

=( AL + A∆L + ∆AL + ∆A ∆L – AL)/AL

= ∆L / L+ ∆A/ A + ∆A/ A. ∆L / L

= SL + SA + SL. SA

Therefore, SV = SL + SA + SL. SA

Typical Values of Swelling of Textile Fibers

| FIBER | AREA SWELL% | DIA SWELL% | AXIAL SWELL% | VOLUME SWELL% |

|---|---|---|---|---|

| Cotton | 40 | 20 | 0.1 | — |

| Jute | 40 | 20 | — | — |

| Viscose | 67 | 35 | 3.7 | 119 |

| Wool | 25 | 14.8 | — | 37 |

| Silk | 19 | 16.5 | 16 | 30 |

REFERENCES

Physical Properties of Textile fibres by William Ernest Morton and J. W. S. Hearle