Round Knife Cutting Machine for Cloths – An Overview

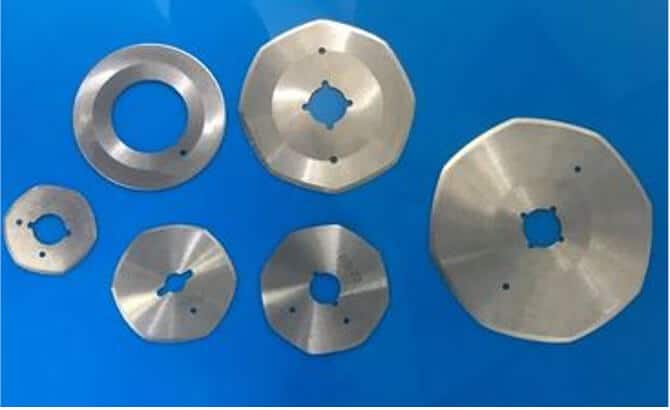

In the garments industry, a round knife cutting machine is used for fabric cutting. Its cutter/blade is round and kind of octagonal, that’s why it is named that way.

However, this tool isn’t as heavily employed in an industrial manufacturing setting as the straight knife cutting machine. It is used for some specific purpose and in small production.

The unit is compact plus very flexible. Thus, it has gained popularity in the garment industry for its compactness and flexibility. As the cutting device is round, the machine cannot be used to cut notches, and the height of the cut spread can be only approximately ¼ of the knife diameter.

Features of Rotary Fabric Cutting Machine

- Round knife cutting machine is more costly than its straight knife counterpart

- It boasts a round and slightly octagonal knife with a sharp edge

- Diameter of the knife differs from 2.362 -7.874 inch or 6 -20cm

- Here, we use the manual grinder for grinding blade

- There are basically 3 sorts of cut edges that can be utilized for cutting various types of fabric. Such as,

- Waved edge

- Toothed edge

- Circular edge

- Motor RPM depends on the machine – varying from 800-1600 RPM

- Equips a handle, which is directly connected with the knife

- Due to its low weight, it offers excellent maneuverability

- In most cases, the knife has to be lubricated manually

- Fabric is cut down by a rotating knife

- Due to its high flexibility, we can easily cut shapes that are non-linear into the fabric

- While cutting the fabric plies, the required tension that’s needed on the fabric surface is provided by the base plate

- Diameter-wise, a maximum of 40% may get utilized for cutting

- Other main parts of this machine are the base plate, electric motor, handle & knife guard

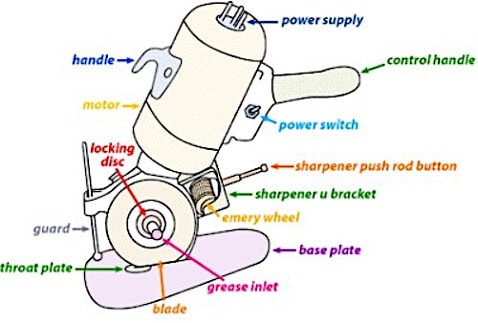

Main Parts of a Rotary Cutter

1. Handle

The handle is the part of the knife that you hold with your hand. It is made out of a durable material and has a comfortable grip to make it easy to use.

2. Motor

The motor is what powers the knife and makes it cut through fabric quickly and easily.

3. Power Switch

Allows you to turn the knife on and off as needed.

4. Blade

It does the cutting and is made out of very sharp metal; needs to be handled with care.

5. Throat Plate

It’s the piece of metal at the base of the blade that helps to guide and hold the fabric in place as it is being cut.

6. Base Plate

The base plate is what holds the fabric in place while you are cutting it. It has a grid pattern on it so that you can make accurate cuts every time.

7. Central Handle

It gives you more control over the knife as you are using it, plus it helps keep your hand away from the blade so that you don’t get injured.

8. Power Supply

Plugs into an outlet and provides power to the motor so that it can run.

9. Sharpener Push Rod Button

Located on the bottom of the knife and allows you to use a sharpening tool to keep your blade nice and sharp.

10. Locking Disc

Helps secure the blade in place when you are not using it. This prevents accidents from happening.

11. Guard

A piece of metal surrounds the blade and helps keep you safe while you are using the knife. It prevents your hand from coming in contact with the sharp edge of the blade.

12. Grease Inlet

The grease inlet supplies lubricant to the knife so that it can run smoothly. This keeps parts moving freely and prevents them from getting damaged over time.

13. Emery Wheel

Used for sharpening the blade when needed. It has a rough surface that grinds away any imperfections on the edge of the blade, leaving it nice and sharp again.

Types of Knives That Are Used in a Rotary Cutter

- Round knife

- Bowie knife

- Throwing knife

- Sharpening knife

- Utility knife

- Automatic knife

- Cutter Knife

The Function of Main Parts

- Handle: It is used to hold the machine perfectly.

- Motor: It provides motion to the blade.

- Power switch: It is used to turn the machine on/off.

- Blade/ knife: It cuts the fabric.

- Thread plate: It aids in cutting the fabric.

- Base plate: It holds the full machine and creates some tension on the fabric ply so that blade can cut perfectly.

- Power supply: It supplies power to the motor.

- Sharpener push rod button: It pushes the sharpener to sharpen the blade

- Sharpening mechanism: The blade sharpening mechanism is on either side of the blade. The mechanism is used to be cleaned after every usage of this machine.

- Locking disc: It holds the knife position.

- Guard: To avoid direct contact of hands with the knife during the cutting process.

Cutting Process of a Typical Round Knife Fabric Cutter

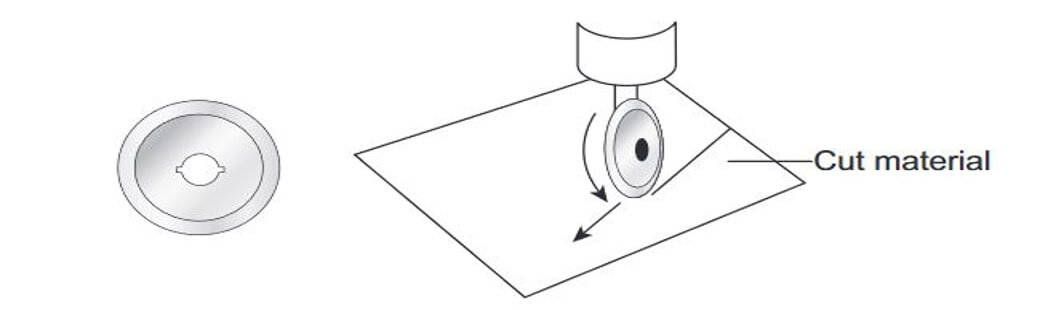

Rotary blade knife (‘Pizza Wheel’ type cutter) is circular and rolls over the material (see Figure). Rotary blade knives are used in single-ply cutters to cut the contours of the components. This type of mechanism is also employed in a typical electric fabric cutter machine for crafters and DIY enthusiasts.

How to Sharpen the Blade of a Rotary Cutter

The process is pretty straightforward.

First, get a feel of pressing the emery roller against the cutting blade like in the video shown below by our expert.

Now, we have to do the same while the blade is running. See the video below for a better understanding.

And that’s pretty much it.

Don’t forget to lubricate your rotary cutter from time to time using the grease inlet.

Advantages of Round Knife Fabric Cutters

- We can easily cut mild curvatures with this machine

- Effortless to maneuver, thanks to its compact size

- Perfect tool when the lay height is small

- Can easily cut both single-ply plus multiple layers of fabric (maximum 20-30 ply)

- Its cutting efficiency is more than 10 times higher than the straight knife cutting machine.

- Finds the most use in suit-making

Disadvantages of Round Knife Fabric Cutters

- Knife height of this machine is very low

- For grinding the knife, you’ll find a manual grinder

- Compared to its counterparts, the revolutions of the cutting blade are pretty low

- Its productivity is low because it can cut a very low number of fabric ply

- High curve lines can be a tough nut to crack with this tool

- Due to low productivity, it is not found in bulk production

- Manually Lubricating is done on this machine

- Throwing knife requires a very skilled operator to cut the fabric

Uses of Rotary Knife Cutting Machine

Again, as we mentioned, the tool is highly flexible, thus can be maneuvered around the curvatures of the cutting lines. Of course, the curvatures should be manageable, i.e., not too extreme. Thus, you’ll see this type of cutting machine to get utilized before per-cutting the required material for the best cobbler sewing machine for leather.

Furthermore, the device can also be used for cutting the large parts of the garment and fabric block cutting from the lay. DIYers, home users, and small manufacturing facilities get the most use out of it. Also, this type of cutting system often gets utilized for suit making.

The Difference Between Round Knife and Straight Knife Cutting Machine

| #SL | Substances | Round Knife | Straight Knife |

|---|---|---|---|

| 01 | Movability | In this arrangement, the machine is stationary, and the fabric is movable. | Here, the machine is movable, but the fabric is fixed. |

| 02 | Knife Thickness | The knife is narrower than the band knife | Knife is thicker |

| 03 | Work Load | Workload is higher than a straight knife. | Workload is less than a round knife. |

| 04 | Cut Angle | Possible to cut the fabric layer at 90°. | Fabric can cut at any angle. |

| 05 | Accident Rate | Accident rate of this machine is low. | Accident rate of this machine is high. |

| 06 | Similar | Round knife is almost like a saw cutter. | Straight knife is not like a saw cutter. |

| 07 | Cut Possibility | Not possible to cut directly. | In this machine, there has possible to cut fabric. |

Conclusion

This machine is very lightweight, small in size, and flexible to move. Due to these reasons, this machine is becoming popular day by day in the apparel industry. You’ll have an easy time cutting your fabric with this machine with the help of a good French curve ruler set. It is decided whether Round Knife Cutting Machine will be used depending on the final product and the quantity of the product.