Yarn Winding: Soft Winding and Hard Winding Machines

Before we get started, we would suggest you to read our previous post covering the basics of yarn winding technologies. If you have read that, then you already know there are 3 types of winding technologies –

- Non-precision/ Drum Winding

- Precision Winding

- Digicone/ Hybrid/ Conotronic Winding

In general, non-precision winding is mainly used in the hard winding section, and the precision and hybrid winding are used in the winding section.

Let’s get started with soft winding machines first.

Different Parts and Yarn Path Diagram of Soft Winding Machine

Among all the soft winding machine that are available in the market today, SSM and FADIS are the most dominant ones. They have some very similar features and some not so similar ones. We’ll go one by one. Let’s start with the Swiss one first; the SSM.

Yarn Path Diagram of SSM TW2W Soft Winding Machine

Stage – 1: Yarn Guide (Pig-tail Type)

Stage – 2:Feeder (Rotating)

Stage – 3: Disc Tensioner

Stage – 4: Knot Catcher

Stage – 5: Moving Guide (Gives Traverse Motion)

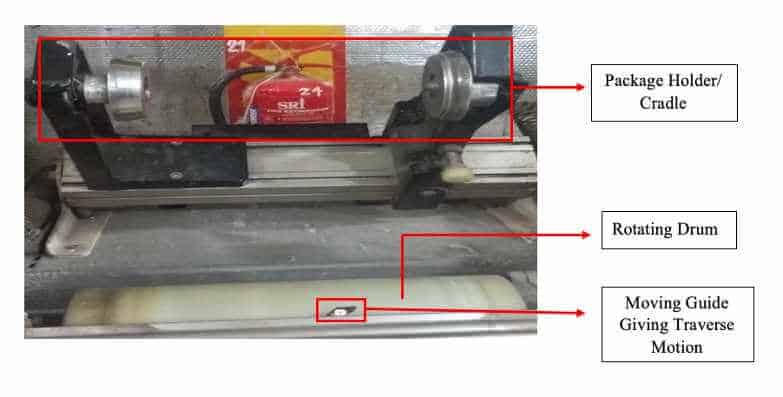

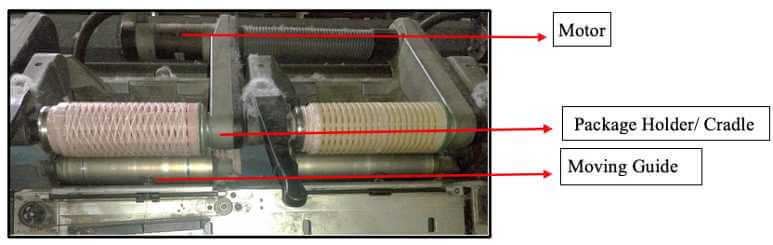

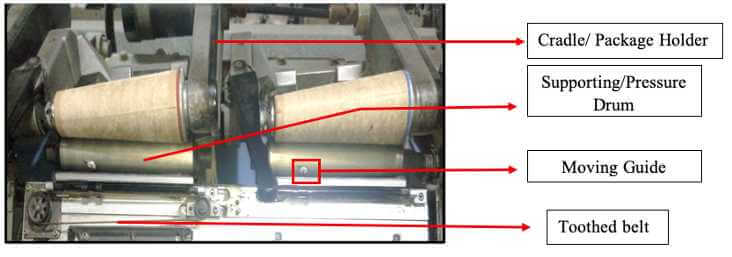

Winding Arrangement of SSM TW2W

- When the package holder is engaged, the package is indirectly driven.

- This type of driving system is also called “Friction Drive”.

- The traverse motion is given by the moving guide.

Yarn Path Diagram of SSM PS6W Soft Winding Machine

Stage – 1: Yarn Guide

Stage – 2: Feeder (Rotating)

Stage – 3: Disc Tensioner

Stage – 4: Knot Catcher

Stage – 5: Sensor (Yarn Breakage Detector)

Stage – 6: Rotating Blade

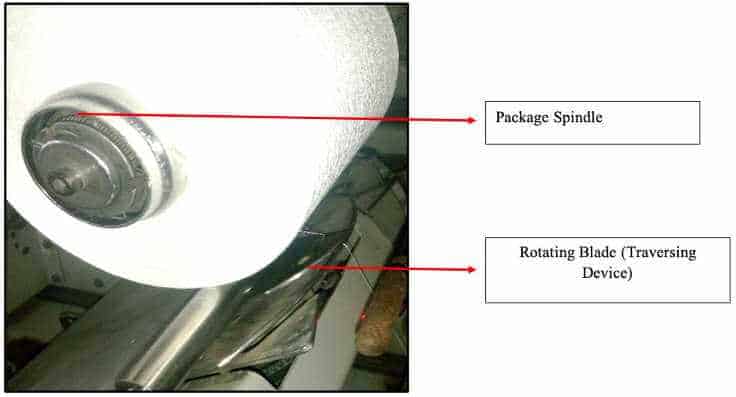

Winding Arrangement of SSM PS6W

- The package is driven directly by a motor.

- The traversing motion is given by rotating/propeller blades.

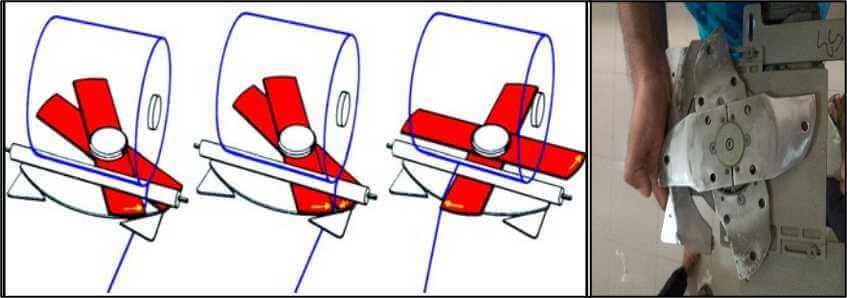

Traversing Mechanism (Left) & Propeller Blades (Right) of SSM PS6-W

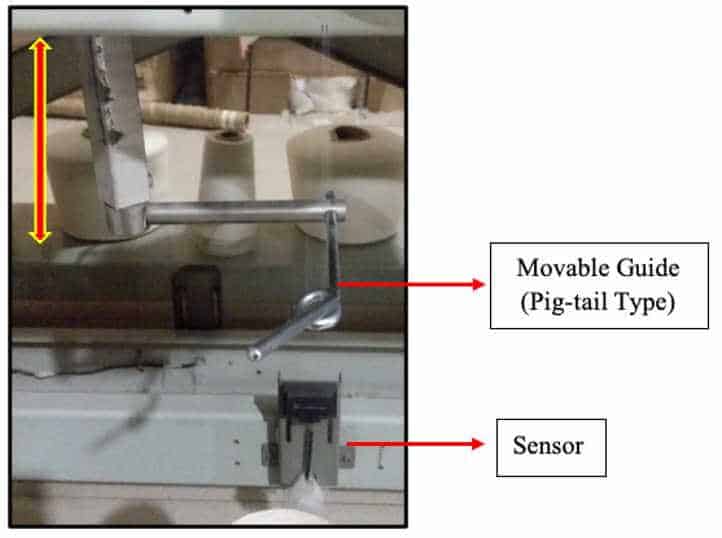

Balloon Control Guide/ Balloon Breaker of PS6-W (2011)

- There are two models of PS6-W: One which came out in 2007 (PS6-W) & the other one came out in 2011 (PS6 Plus-W).

- PS6-W (2007) model don’t have balloon control guide, but the PS6 Plus-W has it.

- If the space between the package & guide is too long then the diameter of the balloon would be higher which will lead to higher hydrodynamic drag (friction between air & the yarn). This can lead to yarn breakage.

- Here the guide can descend & ascend according to the balloon diameter. It works as a Balloon Breaker.

Yarn Path Diagram of FADIS P300 Soft Winding Machine

This Italy based machine has some unique features. We’ll discuss them one by one. But first, let’s take go over its yarn path.

Stage – 1: Yarn Guide (Closed Type)

Stage – 2:Feeder (Rotating)

Stage – 3: Yarn Guide

Stage – 4:Spring Tensioner

Stage – 5: Yarn Guide (Pig-tail Type)

Stage – 6:Yarn Clearer & Tensioner

Stage – 7: Sensor (Detection of Yarn Breakage)

Stage – 8:Yarn Guide (Open Type)

Stage – 9: Moving Guide

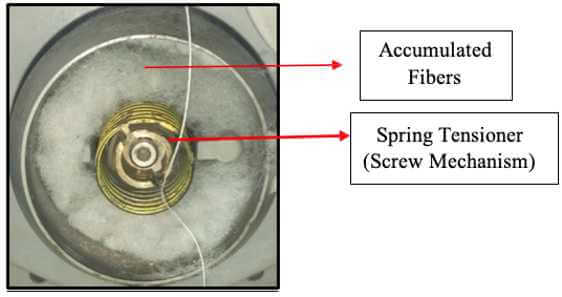

Unique Yarn Clearer and Tensioner of FADIS Soft Winder

I think you’ve already noticed from the above yarn path diagram that this one’s yarn clearer and tensioner looks different. And yes it is! We’ve talked about the tension setting of winders in a separate post if you’re interested. Let’s take a look at how these two mechanisms work in this single unit.

1. Yarn Clearing

2. Yarn Tensioning

Winding Arrangement of FADIS P300

- One spindle gets directly driven by the motor & the other one gets the drive through a shaft connected to the motor.

- A moving guide gives the traverse motion. Again, the guide is connected to the adjacent guide by a toothed belt.

- It is possible to make rounder packages which leads to better dyeing performance. The traverse is relatively shorter so package to package gap is higher.

Well, that marks the end of our lesson on the soft winding machines. Now, we’ll glance over the hard winding machines.

Different Parts and Yarn Path Diagram of Hard Winding Machine

We already know that the hard winding machines have winding systems which work on Random Winding principal that has the following properties –

Properties of Non-precsion/ Drum Winding

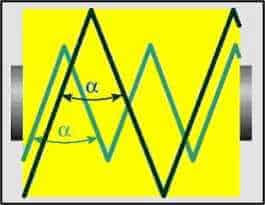

- The winding angle remains constant.

- As the diameter of the package increases, number of coils per turn of the package decreases. So, the package is softer at the outer layers.

- When the winding ratio becomes a whole number/integer, the yarn is laid over the yarn wound in the previous traverse, resulting in the formation of a “ribbon”.

An ideal Hard Winding machine should have the following features –

- Anti-patterning device

- Weight release mechanism

- Length measuring device

- Balloon breakers

- Yarn tension controlling system

Yarn Path Diagram of SSM CW2-W Hard Winding Machine

Stage – 1: Yarn Guide (Pig-tail Type)

Stage – 2: Disc Tensioner (Hand Adjustable)

Stage – 3: Waxing Unit

Stage – 4: Knot Catcher

Stage – 5: Sensor

Stage – 6: Winding Drum (Grooved)

Yarn Path Diagram of SSM CW8-W Hard Winding Machine

Stage – 1: Yarn Guide (Pig-tail Type)

Stage – 2: Disc Tensioner (Hand Adjustable)

Stage – 3: Waxing Unit (Rotating)

Stage – 4: Knot Catcher

Stage – 5: Sensor

Stage – 6: Winding Drum (Grooved)

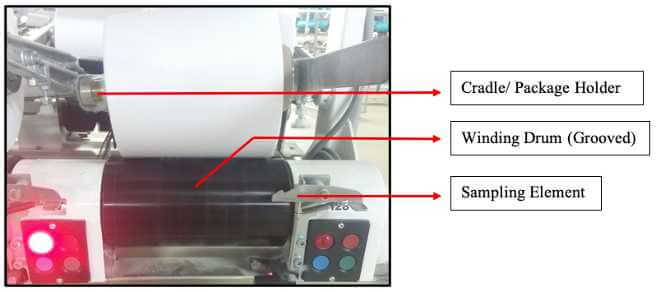

Winding Arrangement of SSM CW2-W & CW8-W

- Here the package is indirectly driven by the surface contact a rotating grooved drum.

- The traverse motion is given by the grooving of the drum.

- The grooved angle is fixed so only “Random Winding” is possible.

- As the diameter of the package increases, number of coils per turn of the package decreases. So, the package is softer at the outer layers.

Yarn Path Diagram of FADIS P300

Stage – 1: Yarn Guide (Closed Type)

Stage – 2:Feeder (Rotating)

Stage – 3: Yarn Guide

Stage – 4: Spring Tensioner

Stage – 5: Yarn Guide (Pig-tail Type)

Stage – 6:Yarn Clearer and Tensioner

Stage – 7: Sensor (Detection of Yarn Breakage)

Stage – 8:Waxing Unit (Rotating)

Stage – 9: Moving Guide

Winding Arrangement of FADIS P300

- The winding arrangement is very similar to that of the soft winding machine. The only difference lies in the fed bobbin which is conical.

Differences in Waxing Units of Hard Winding Machines

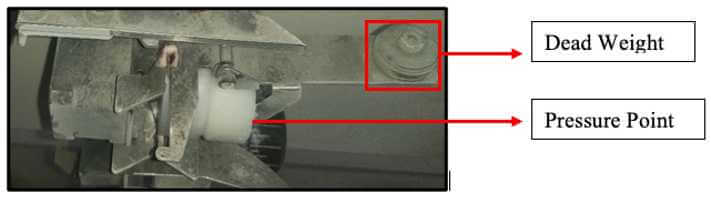

You might have noticed from the diagrams that the waxing units look different. That’s because their mechanisms differ as well.

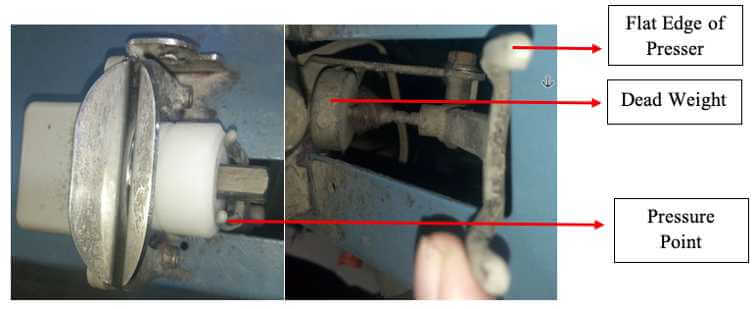

1. Waxing Unit of SSM CW2-W Hard Winding Machine

- As we can see from the above figure, the waxes are pressurized by dead weights.

- The weights are changeable but its time consuming.

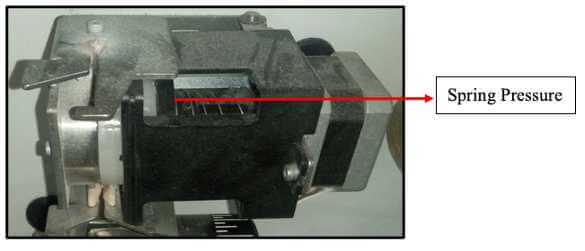

2. Waxing Unit of SSM CW8-W Hard Winding Machine

There are two variations of CW8-W. The older one (2011) has the following arrangement –

- As we can see from the above figure, the loading can be varied easily.

The newest one (2016) has the following arrangement –

- As we can see the pressure is applied by a spring. To increase the pressure more wax can be inserted.

- This unit has a major advantage over other units which is lower wax wastage.

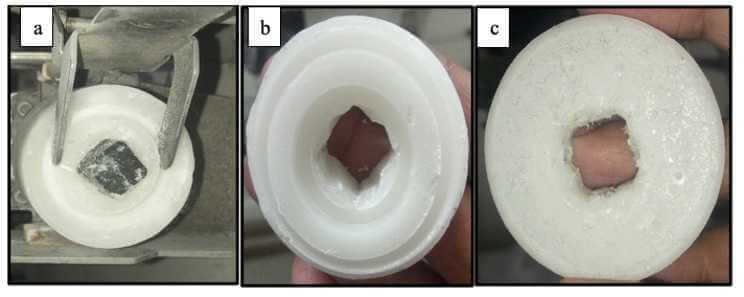

3. Waxing Unit of FADIS P300 Hard Winding Machine

- Here the pressure is applied by dead weight which is fixed.

- As the presser is made out of plastic & the edges are relatively flat wax wastage is lower.

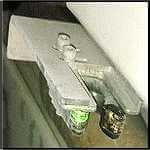

Sampling Device of Hard Winding Machine

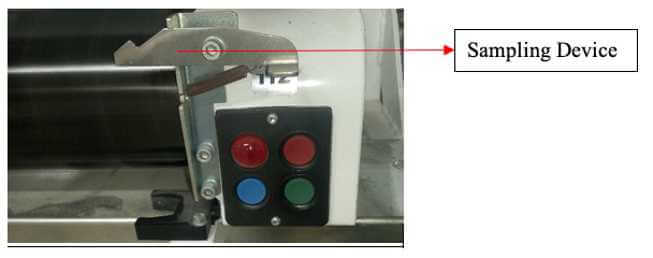

Among the two brands, the SSM CW8-W(2016) model had a sampling device, which comes very handy.

- The newest SSM CW8-W(2016) & CW2-W has sampling device. When engaged the yarn will wind on the extreme edge of the package, which will facilitate the sampling process.

Frequently Asked Questions

1. Can we use hard winding machines as soft winding?

Technically, you can after certain modifications, starting with the bobbin holder. The waxing unit needs to go as well. But it’s not worth the trouble because patterning will be unavoidable. So, you won’t get the desired dyeing result that you would want. Also, there’s not much benefit in terms of production speed either.

2. What is the winding ratio of a drum winding machine?

It’s very simple to measure. All you have to do is measure the no. of coil that’s formed by its double traverse. Initially, the winding ratio would double the amount of coil that’s grooved on the drum. But as the diameter of the package increases, you’d see a fall in winding ratio.

3. Why can we make pineapple package with FADIS but not with SSM?

Well, it has got to do with the traverse length. FADIS lets us change the traverse length gradually. As the traverse length decreases the package becomes rounder. The moving guide facilitates this process.

Unfortunately, the SSM machines don’t come with traverse length changing features. The rotating blade system isn’t ideal for traverse length variations during package build-ups.

Well, that’s it for now. If you’re interested to find the best yarn ball winder, do give our other article a read. I hope after reading this article you have a thorough understanding of the similarities and the differences between the machines of these two giant brands.

REFERENCES