Motion Transmitting Devices & Their Relation to Yarn Manufacturing

Motion Transmission

Motions are transmitted from the source Motor to different Rollers in machines like Carding, Draw-frame, Simplex, Ring-Frame etc. through some motion transmitting devices such as-

- Gears

- Chain & Sprocket

- Belt-pulley etc.

It is important to understand that when devices are placed in same shaft the motion is only ‘transferred’, on the other hand when devices are in contact with each other motion is ‘transmitted’.

What is The Difference Between ‘Transferred’ & ‘Transmitted’ Motion ?

- If two gears are placed in the same shaft the Rotation Per Minute (RPM) remains same for the both of the gears, doesn’t matter if they are differently sized. The motion is only Transferred from one gear to another here.

- On the other hand, when two gears are in contact with each other the RPM of them are varied according to their size. Here, motion is Transmitted.

Reason of Variation in RPM

When motion goes from one device to another in contact with each other, It depends upon how much distance a device can cover other device in one revolution.

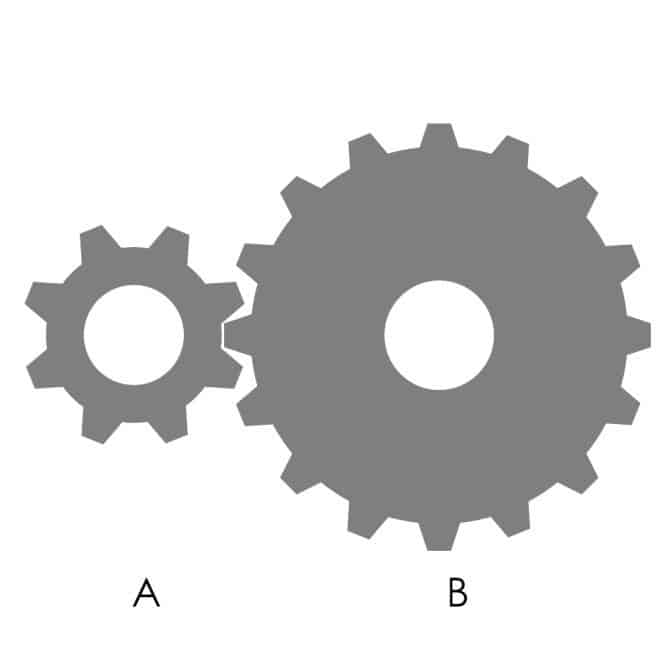

Consider Two Gears A and B as shown in the above Figure.

Let’s say,

The total no. of teeth in A = 8

The total no. of teeth in B = 16

When A rotates one time each of the teeth comes back to exactly the same place where they were at the initiation of the rotation completing one revolution. Same goes for B.

From the Figure we see that one tooth of A covers one tooth of B. when A completes one revolution all eight teeth are rotated for one time. These eight teeth cover eight teeth of B. But to get one revolution from B all the sixteen teeth must be covered. To cover other eight teeth of B, gear A must be rotated for another complete revolution.

Therefore, to get one rotation from gear B, gear A must be rotated two times. We can see that rpm of gear A is twice the rpm of gear B. Or it also can be said that rpm of gear B is half of the rpm of gear A .

From the above discussion we can conclude that-

If motion is transmitted from smaller device to bigger device rpm reduces or if motion is transmitted from bigger device to smaller device rpm increases.

Example :

In a Rickshaw, Sprocket that’s pulled by the puller is bigger than the attached sprocket to the Back Tires. Thus the motion is transmitted from bigger to smaller device and rpm is increased.

Driver and Driven:

The device that transmits the motion to another device is driver. And the device that gets the motion is called driven. ‘A’ is driver and ‘B’ is driven in the above Figure.

To increase rpm Driver should be bigger than the Driven and to decrease the rpm Driver should be smaller than Driven

Some Common Terms Used in Yarn Manufacturing

Draft Change Pinion (D.C.P.)

It is the device that is used to change the draft of a machine by changing the teeth number or size of the device, they are most of the time gear or pinion. Draft is the difference ratio of the surface speed between back roller and front roller. Hence, it may be also said that it’s the difference of rpm.

Why RPM of front roller isn’t changed that much in practical cases ?

- The front roller speed determines the production.

- While changing the draft of the machine the production can’t be hampered.

- So, draft can only be changed by changing the rpm of back roller.

Varying the amount of input material draft can be changed.

The difference of rpm between front roller ant back roller when increases, draft also increases and vice versa. Since changing draft lies changing difference of rpm between front roller and back roller, D.C.P. must be placed between front roller and back roller. D.C.P. can not be placed before front roller. It might be at driver position or at driven position.

What Are The Necessary Parameters to Increase/ Decrease Draft ?

- When draft is increased that means back roller rpm should be decreased. To achieve that if D.C.P. is in driver position, the size of D.C.P. should be decreased. On the other hand if D.C.P. is in driven position, the size of D.C.P. should be increased. So that, rpm of every gears and corresponding rollers will be decreased. And finally rpm of back roller is decreased and draft is increased.

- To decrease draft if D.C.P. is at driver position, it’s size should be increased. And if it’s in the driven position, it’s size should be decreased.

(here motion is transmitted from front roller to back roller)

Twist Change Pinion (T.C.P)

Like D.C.P. it is used to change the twist of the product per unit length by changing its teeth number or size. The twist is imparted in the final product of the machine by differencing rpm between spindle and front roller. To change twist the spindle speed is not changed. So that, front roller delivery is changed. If front roller delivery increases, the twist per unit length decreases and vice-versa.

T.C.P. must be placed anywhere between spindle and front roller so that changing T.C.P. does not harm draft.

To increase twist per unit length, front roller delivery that is rpm must be decreased.

If T.C.P is at driver position its size should be decreased. If T.C.P. is at driven position its size is increased. When twist per unit length is decreased, the rpm of front roller is increased. To do that size of T.C.P. is increased when at driver position. On the other hand size is decreased when it as at driven position.

When T.C.P. is changed the rpm of gears and corresponding rollers after it also changed including back and front roller.

Since rpm of back and front roller changes with same ratio, draft is not harmed or changed at all, only front roller delivery is changed.