Geotextiles – Types | Properties | Use

The application of technical textile has reached its peak in recent years—mostly for automotive applications. And geotextile is one of the most promising branches of functional textiles.

Let’s start with the most basic queries —

What is Geotextile?

The Textile Institute defined geotextiles as —

“Any permeable textile material used for filtration, drainage, separation, reinforcement and stabilization purposes as an integral part of civil engineering structures of earth, rock or other constructional materials.”

To rephrase it simply, geotextiles are permeable textile material that is used for civil engineering purposes (roads, drains, land reclamation purposes, harbor works, etc.).

Now, let us dig deep into these functional materials.

What Are the Main Types of Geotextile?

Based on the manufacturing procedures, geotextiles can be classified as —

- Woven

- Knitted

- Heat-bonded non-woven

- Needle-punched non-woven

1. Woven Geotextiles

These fabrics are made in looms. Their rectilinear construction varies upon the type of component fiber and weaves structure. The main advantage of woven geotextiles in terms of reinforcement is that they can absorb the stress with minimal mechanical elongation. It means that they exhibit excellent stiffness properties.

The use of woven geotextiles can be described in two forms.

- The Lighter Weight Form: Filters, soil separators, erosion control textiles, etc.

- The Heavier Weight Form: Embankment support.

2. Knitted Geotextiles

The knitted geotextiles are mainly warp-knitted textiles made from warp-knitting machines. It can produce fine filter, medium meshes, and large diameter soil reinforcement fabric. Their main advantage is that they can provide high strength at a low cost.

These are mainly used for soil reinforcement and embankment support.

3. Heat-Bonded Non-Woven Geotextiles

These fabrics are produced by carrying out the following steps—

- Lying continuous fine filaments into a moving belt randomly

- Passing them between heated roller systems

- When the hot roller melts the filaments partially, they acquire their coherence and strength

They form a thin sheet of textiles. This process is limited to products with less thickness.

4. Needle-Punched Non-Woven Geotextiles

Needle-Punched Non-Woven is produced by passing blended webs of continuous or staple filaments through banks of several reciprocating barbed needles. When the needles create entanglements among the filaments, they acquire their coherence and strength.

In this process, thickness up to 10mm and weight up to 2000g/m-2 can be achieved.

Geotextiles As Geosynthetics

Geotextile is actaully a type of geosynthetics. Now, geosynthetics can be defined as the membranes used in contact with or within the soil.

So, let’s look at other types of geosynthetics —

- Geomembranes

- Geogrids

- Geonets

- Geocomposite

- Geomat

- Geocell

- Biomat and Bionet

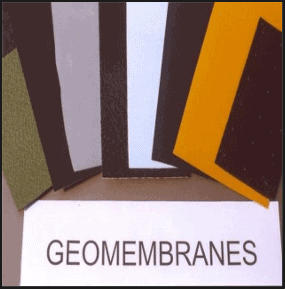

1. Geomembranes

Geomembranes are generally synthetic or bituminous manufactured sheet acting as resistant material. They are mainly used as a liquid-vapor barrier in landfills and waste containment facilities. The reason behind this application is its extremely low permeability.

They can be classified as —

Calendered Geomembranes

A molten viscous formulation of Polypropylene or Polyvinyl Chloride is passed and flattened between counter-rotating rollers.

Extruded Geomembranes

Molten polymer chips are forced through a die with the help of a screw extruder. They are followed by a conveyor belt and finally pulled by a nip roller above the die.

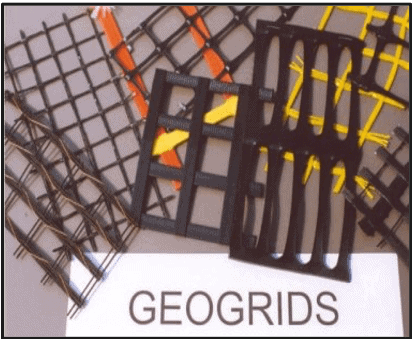

2. Geogrids

Geogrids are mainly manufactured sheets (single or multi-layer) having a regular network of integrally associated parts. High-density polyethylene or polypropylene is extruded and stretched, or polyester yarns are weaved or knitted and finally coated to make geogrids.

As they have larger openings (apertures), they are suitable for reinforcement materials. Five types of geogrids are available.

- Undirectional

- Bi-directional

- Extruded

- Woven

- Bonded

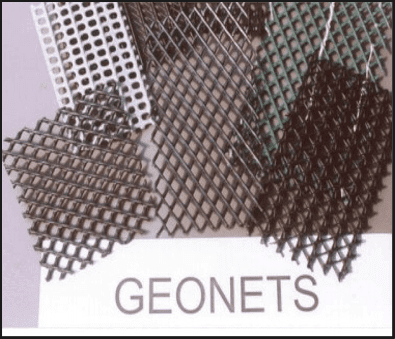

3. Geonets

Geonets are mainly made from polyethylene. A matrix or net is formed when the molten polymer is extruded through slits in counter-rotating dies. Mainly used in the drainage system as they do not have sufficient strength.

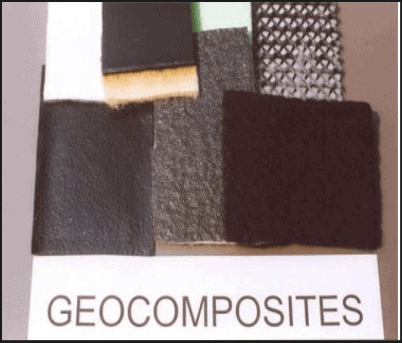

4. Geocomposite

Geocomposites are a mixture of geotextile-geogrid, geotextile-geomembrane, and geogrid-geomembrane or one of them with another material.

5. Geomat

Geomat is an irregular network of fibers, yarns, filaments in the form of a manufactured sheet. They have higher openings than others.

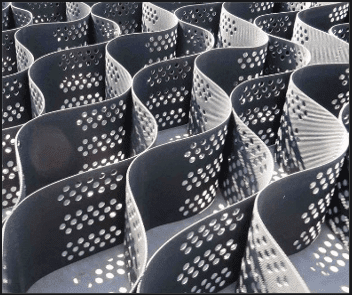

6. Geocell

Geocell includes a regular open network of connected stripes. They are linked by extrusion or adhesion.

7. Biomat & Bionet

Biomat and Bionet are mainly natural and biodegradable manufacturer sheets. Biomat consists of fibers by one or two layers of meshes, and bionet consists of yarns.

What Are the Main Properties of Geotextile?

Geotextile requires three types of properties– Mechanical Response, Filtrationg Ability, Chemical Resistance. Geotextiles must have the mechanical response to withstand the stresses and strains inherent in their application, as well as the ability to filter out fine particles while still allowing water to pass through. Additionally, they need to have chemical resistance to ensure they can withstand exposure to various environmental conditions. These properties are essential for the successful performance of geotextiles in engineering and construction projects. When considering these requirements, it is important to take into account nonwoven fabric properties, as they play a crucial role in determining the overall effectiveness and durability of geotextiles. Nonwoven fabric properties such as strength, permeability, and abrasion resistance are key factors in satisfying the mechanical response, filtration ability, and chemical resistance needed for geotextile performance.

1. Mechanical Responses

It is the ability to perform in a stressed condition and resist damage in severe environmental conditions. Geotextile should absorb the stresses and not degrade during its proposed lifetime. This ability depends on the stiffness of the material and the ability to resist creep under any given load-condition.

Practically, geotextiles generally made in composite form. One material of the composite works for tensile strength and other works for damage protection.

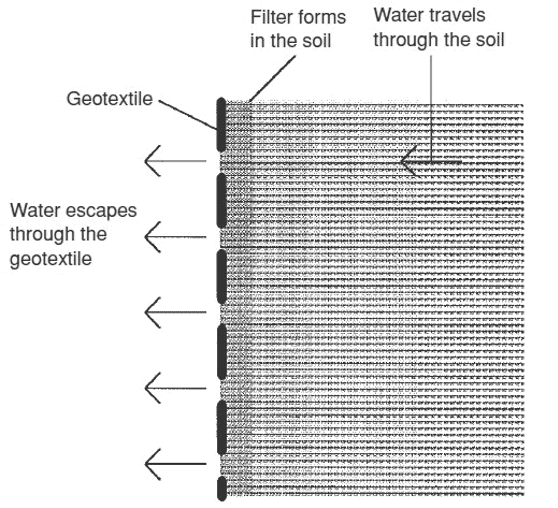

2. Filtration Ability

Geotextile should be able to hold an entirely new prepared soil surface when water gets passed through it. Thus geotextile prevents the surface from breakdown.

3. Chemical Resistance

Deterioration of geotextile may be caused by organic (micro- and macrofaunas), inorganic agents (extreme pH conditions), light exposure, and time change during its lifetime.

What is the Use of Geotextile?

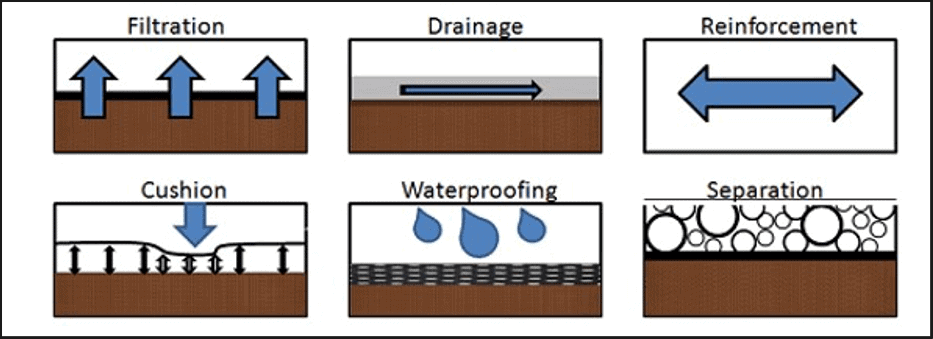

Geotextiles can be employed in multiple functional purposes ranging from filtration and drainage to waterproofing and separation. The following areas mostly require these functions –

- Highways, flight strips, or any paved surface for that matter

- River embankments

- Parks

- Dumping grounds

- Walkways

- Car parks

- Underground conduits

- Airport runways

- Pipe trenches

Let’s see the below illustrations to get a clear idea of the functions we talked about –

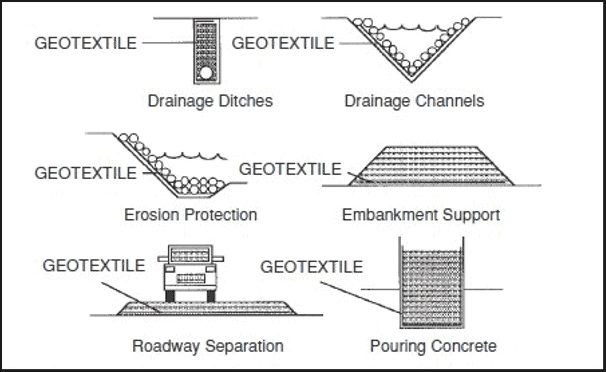

Now, let’s see the illustrations of some of the applications –

Frequently Asked Questions

It’s impossible to cover every aspect of Geotextiles in a single post. Here, I’ll try to answer some of the most common queries regarding geotextiles –

1. Is geotextile necessary?

Obviously, yes, if you want to prevent the loss of soil in the embankments, roads, or other places. Because these are the places where water comes in contact with the soil, and stress also applied upon them.

2. What are the differences between geotextile and geomembrane?

The most obvious differences are –

- Geotextile is water permeable while geomembrane is not.

- Geotextile is used in reinforcement, while geomembrane is used in seepage prevention.

- The primary materials of geotextile are geotextile cloth and non woven fabric, while high-density polyethylene is mainly used in geomembrane.

3. Does water go through geotextile?

Yes, geotextiles allow water to flow through them. They act as a filter.

4. How long does geotextile last?

The lifespan of geotextile depends on several factors. Some of these factors are – the raw material used to prepare the fabric, its physical structure, consistency, and quality of the manufacturing process, end-use, etc. So, there is no definite answer to it.

However, geotextiles made from polyester and polypropylene have almost 200 years of lifespan if not exposed to UV light.

5. Can geotextiles be used as fabric pots?

Yes, geotextiles can be used as fabric pots. Geotextiles are a type of porous fabric. They are lightweight, strong, and flexible, making them ideal for use in fabric grow pots.

Geotextiles allow for proper drainage and aeration of the soil, while still providing a barrier to keep the soil in place. The fabric can also be used to control the amount of water, nutrients, and oxygen that reach the roots of the plants, creating a healthy environment for the plants to thrive.

Geotextiles are also less likely to tear or puncture compared to traditional plastic grow pots, making them a great alternative for long-term use.

6. How do you install geotextile fabric?

It actually varies from fabric to fabric. But to give you a general idea, I’ll list the most basic steps to install a geotextile fabric below –

- Step 1: Clean(removing trees from the soil and subgrade material) and prepare the area and fill the soil with granular if pockets exist

- Step 2: Make the subgrade level and smooth

- Step 3: Place the geotextile tightly and flatly according to the recommendation

- Step 4: Overlap the fabric as per specification

- Step 5: Secure the fabric in the overlapping areas and along the edges with suitable material

- Step 6: Fill the place of geotextile loosely