Blending of Cotton-Polyester Fibre to Produce PC/CVC Yarn

What is Blending?

In simple terms, blending is the process of combining two or more materials to achieve a desirable property.

Why Fibre Blending is Necessary?

The most popular reason for blending is that of combining the properties of two or more fibers. Blending of different fibers is also used to increase aesthetic effects in the fabric.

Polyester/cotton blend is an example; a good end use is in suiting. Polyester is a man-made fiber with high abrasion resistance and cotton is a natural fiber and has good moisture absorbency & feel.

What is CVC Yarn?

In a cotton-polyester blended yarn, when the amount of cotton fibre is more than polyester fibre it is called CVC yarn. Here CVC stands for Chief Value of Cotton i.e., the ratio of cotton fibre is always above 50% or more in these yarn types.

Example: 30 s/1 Ne (60/40) CVC Yarn means, It is a 30 count single ply cotton-polyester blended yarn where the ratio of cotton fibre to polyester fibre is 60 to 40.

What is PC Yarn?

A cotton-polyester fibre blended yarn is called PC yarn, but in general where the amount of polyester fibre is more than cotton fibre is called PC yarn. Here PC stands for Polyester Cotton.

Example: 30 s/1 (60/40) Ne PC Yarn means, It is a 30 count single ply cotton-polyester blended yarn where the ratio of polyester fibre to cotton fibre is 60 to 40.

It can be said that every CVC yarn is also PC yarn but all the PC yarns are not CVC yarn.

Blending Process of Cotton-Polyester Fibre

To produce a CVC/PC yarn the fibres must be blended before it reaches to ring frame machine as roving. This blending process mainly can be done in two manners.

1. Fibre Blending

According to the blending ratio of cotton & polyester fibre in the yarn, numbers of cotton & polyester bales are given in the laydown in blowroom using bale management.

Then the both fibres pass consecutively through the fibre plucker machine- mostly used – Uniflock (Rieter) or Blendomat (Trutzschler) machine and then gradually different cleaning machines.

The homogenous blending of fibres takes place at mixing machine- mostly used as- Unimix (Rieter) or Multimixer (Trutzschler) machine. This type of mixing/blending is called fibre blending.

From this type of blending, blended card slivers can be obtained. Then the regular spinning flow chart is followed till ring frame machine to produce PC/CVC blended yarn.

2. Sliver Blending

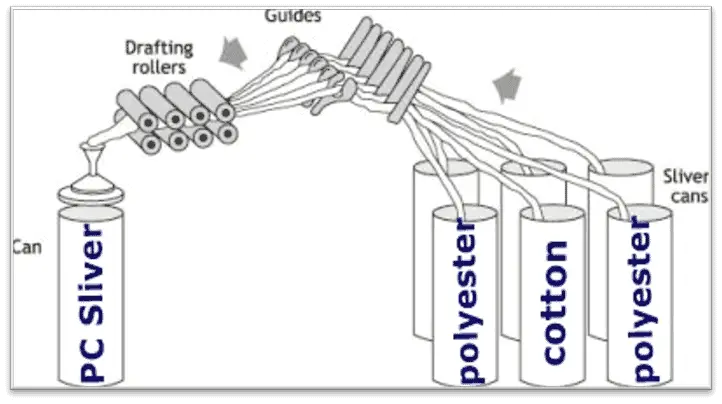

In this process, cotton fibres & polyester fibres are processed through separate machines from blowroom to carding. Then the separate card slivers are made from polyester & cotton.

After that, to ensure better blending, the polyester carded slivers are passed through one phase draw frame which is known as pre-pass phase to keep the sliver hank as optimum as possible.

Then, according to the required blended ratio the slivers are blended in breaker draw frame. In draw frame slivers are doubled, drafted & blended to the required ratio.

Finally, conventional spinning process is followed till ring frame machine to produce PC/CVC yarn.

Which Type of Blending is Better?

After a lot of experiments, it has been noticed that sliver blending is slightly better than fibre blending.

That is because, in sliver blending, the ratio of cotton & polyester can be maintained more precisely than fibre blending. This precision allows manufacturers to achieve desired fabric qualities while optimizing cost and performance. Furthermore, understanding the distinct attributes of each material is crucial; for instance, cotton fiber characteristics explained can enhance the overall quality and comfort of the blended textiles. This level of control over the blend ratio ultimately results in fabrics that cater to specific market needs and consumer preferences. Moreover, manufacturers can innovate with various fabric types explained in detail, ensuring they meet the evolving standards of sustainability and performance in the textile industry. By leveraging advanced technology, they can experiment with diverse blends, creating unique textures and functionalities that appeal to a broader range of consumers. This adaptability not only promotes creativity in design but also reinforces the brand’s commitment to quality and customer satisfaction.

On a side note, if you own an Ashford Kiwi 3 spinning wheel, you should opt for premixed fibers.