How to Make a Wooden Yarn Ball Winder

Making a DIY wooden yarn ball winder is just what you need to get you out of messy and tangled yarn. However, how to make a wooden yarn ball winder?

Cutting the wooden blank, creating the wooden base, and assembling the winder are the ways you can make a wooden yarn ball winder. Moreover, using a DIY yarn swift and wooden yarn ball winder is the best bet to assure an easy and trouble-free handling of a ball of yarn.

However, DIY wooden yarn ball winders are pretty challenging to make for most people. And that’s why we are going to let you know precisely how to make a DIY yarn ball winder with an easy step-by-step process.

How to Make a Wooden Yarn Ball Winder?

A yarn ball winder works by wrapping the different yarn types into a center-pull ball that clamps tightly onto the table’s surface and doesn’t get tangled at all while you work.

A center spool in DIY yarn ball winders holds the yarn so that it doesn’t roll around distractingly during knitting or crocheting.

Although, it can take a considerable amount of time, especially if you make a wooden yarn ball winder for the first time.

So, to help your knitting easier and faster, below are the step-by-step procedure that you can follow to make a DIY wooden yarn ball winder of your own:

Step 1: Gathering the Necessary Materials

You will need to acquire a handful of materials to prepare to make the DIY yarn ball winder you need. Here is a list of materials you have to gather as the first step in making a DIY yarn ball winder:

- Wooden blank

- Hole saws or lathe machine

- Glue or PVA glue

- Cutting mat

- Scissors

- Wire cutter

- Ruler

- Compass

- Duct tape

- Pencil

- Pliers

- Small clamp

Step 2: Measuring Sizes and Dimensions

Once you are done selecting the kind of yarn ball winder you want to make, the next step is to measure everything properly. Draw out the design on a piece of paper first and add proper dimensions. This will guide you when you cut out and glue the parts in the next steps.

The dimensions and sizes are entirely up to you as it depends on how big you want the yarn ball winder to be. However, the base needs to be bigger than the cylindrical upper part in all cases. Maintaining this ratio will create a beautiful yarn ball winder eventually.

Step 3: Cutting the Wooden Blank

This might be the step that most people will find difficult while making a DIY wooden yarn ball winder. You have to take a thick wood block and turn it into a wooden cylinder shape. Using a lathe machine can be the easiest and fastest way to achieve that.

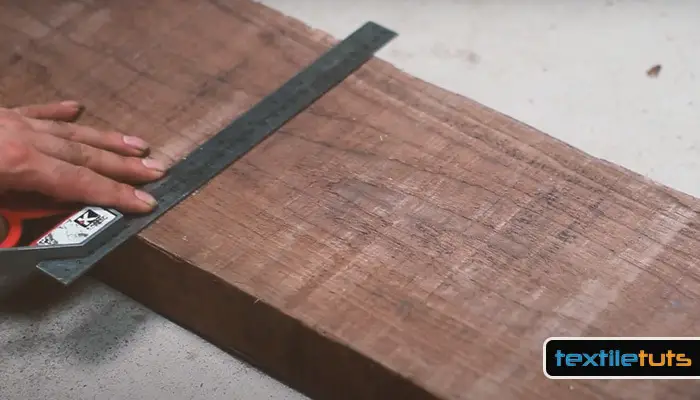

First, you have to draw a line on one side of the wood and another on the other side after rotating it 90 degrees. Moreover, there are two types of action for this job one is spindle turning and the other is bowl turning.

You can choose any of the two operations to make the wooden cylinder shape you want to achieve.

For the spin stabilizer, make a long cylindrical wooden piece. After that, create another cylindrical wooden piece that needs a little shorter length than the previous one.

The second wood piece needs to be cut on one side at a 45-degree angle. You can also use any saw to cut it in a 45-degree diagonal line.

Step 4: Creating the Wooden Base

The next step in making a DIY wooden yarn ball holder is to create a wooden base on top of which the entire yarn ball winder will be placed permanently.

To make the base, take a wooden plank and cut it in a rectangular shape using any saw you see fit. Make sure to smoothen out the edges with sandpaper after the cut is done.

At one side of the base wooden plank, cut through a circular hole for the smaller cylindrical part. So it has to be of the same diameter as the previous parts.

Step 5: Making the Winder

Measure the diameter of the two cylinders made before with a ruler. While taking the measurements, it is necessary to be very careful since wrong measurements can unexpectedly ruin the DIY yarn ball holder.

Using hole saws, cut a wooden plank in a circular shape. The circle’s width can be thick or thin, and it is adjustable.

Pinpoint the center of the circle and draw another circle of the same diameter as the cylinder here with the help of a pencil.

This smaller diameter circle has to be cut off from the piece of the round wood plank. Thus, there will be a hole in the middle of the part.

Step 6: Adding the Wire Guide

For the wire guide, you need to measure the distance between the wooden base and the halfway of the spin stabilizer. Cut the wire with the help of wire cutters of the same length. Using pliers, spiral the wire and insert it through the hole.

The top of the wire needs to be adequately coiled as the yarn will go through it. You need to superglue the wire in place not to move around.

Another piece of rectangular wood has to be on top and super glued to the wire. Thus, the wire guide will be complete.

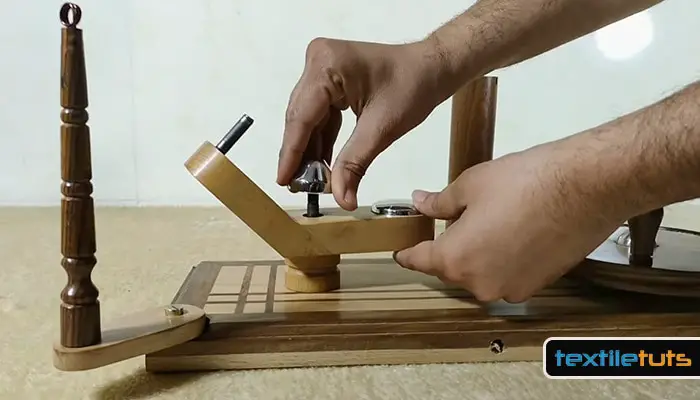

Step 7: Assembling the Yarn Ball Winder

Set up all these parts you have prepared until now. Take the circular part with a hole in the middle and glue both of the cylindrical parts to both sides of the plank.

Make sure that the 45-degree diagonal cut faces this circular plank. If you make no mistakes, the diagonal part will spin when you rotate it. This assembled part is the spin stabilizer.

The entire spin stabilizer has to be placed on the base for the last step. To do that, take the side of the cylindrical wooden part with a bigger length and place it on the hole created on top of the base. Secure the parts together with super glue or PVA glue tightly.

Step 8: Winding the Yarn

Use a clamp to hold your entire winder onto the table. Slip one end of the yarn through the wire guide and take it down through the cylindrical tube of the spin stabilizer.

You can use a bowl or deep cut holder to keep the skein or hank of yarn in. Once this setting is secured, start moving the diagonally cut part clockwise.

While doing this, hold the top of the yarn winder at an angle of 20 degrees in the same direction. That will result in your yarn being winded perfectly around the winder.

Make sure to move the direction of the yarn after 20-30 turns a few times. This way, the ball of yarn will be evenly distributed, making a perfect and beautiful yarn ball.

Bottom Line

So, now you know how to make a wooden yarn ball winder, which will prevent your yarn from tangling and grant you more time to work on your actual project. This also helps maintain the yarn’s elasticity over time so that the fibers are not damaged. Moreover, the yarn ball winder lets you detect any flaws before starting your knitting work.